Piston And Cylinder Kit Industry Knowledge Extension

1) Why is a high-quality Piston And Rings Set critical in automotive car parts?

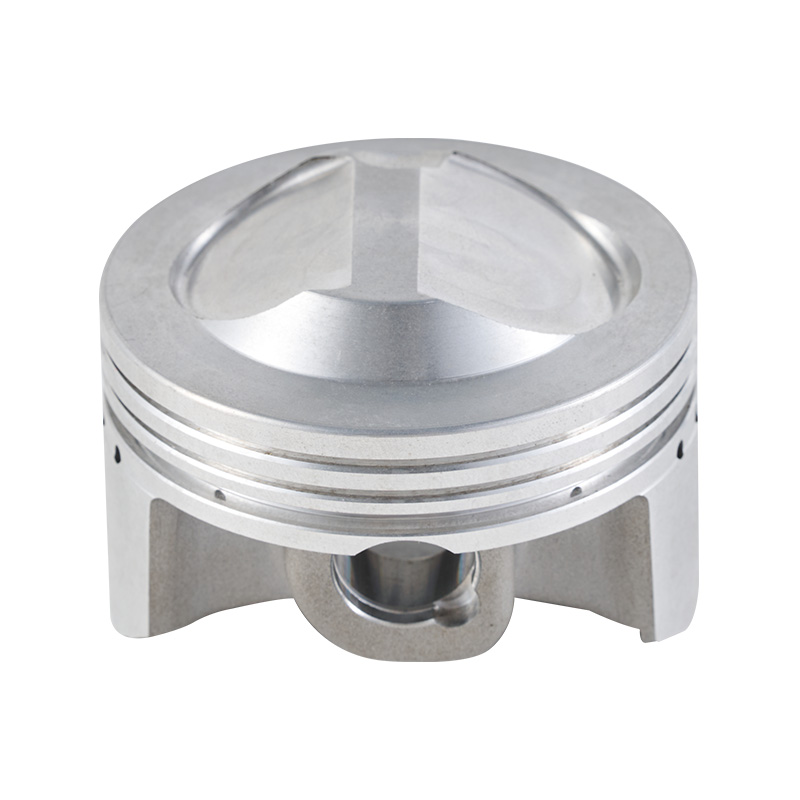

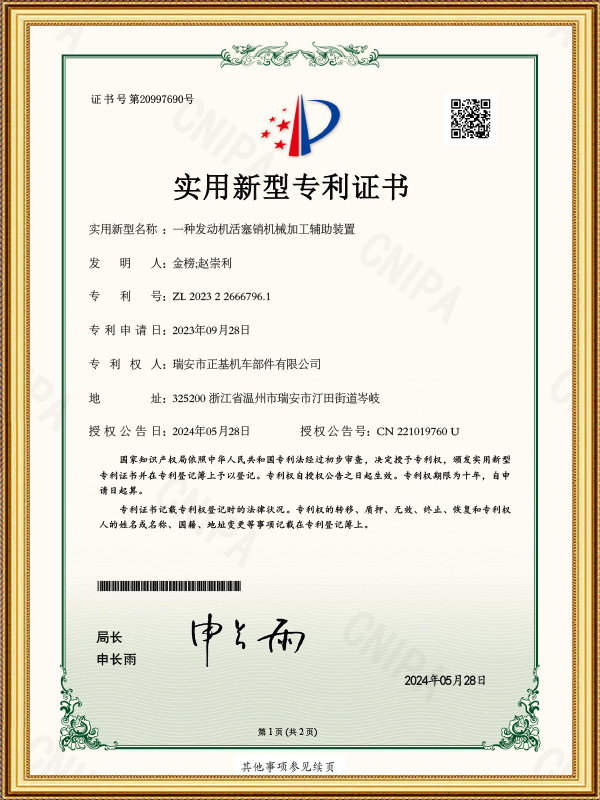

In the field of automotive car parts, the piston and ring system plays a decisive role in engine efficiency, durability, and emission control. As a professional manufacturer, Zhengji designs each Piston And Rings Set as a complete, matched solution rather than individual components.

Key advantages from Zhengji:

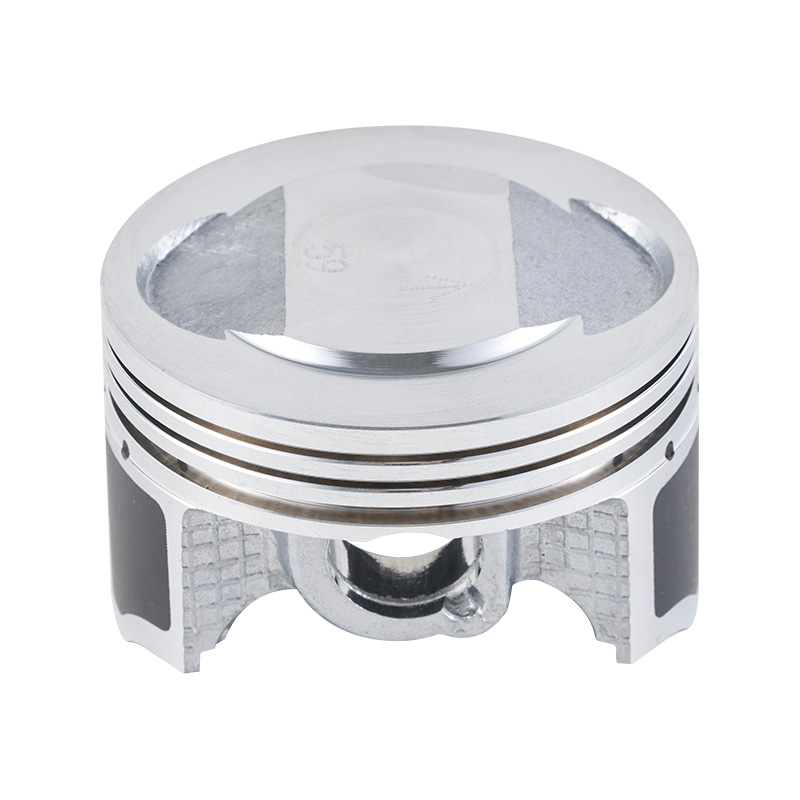

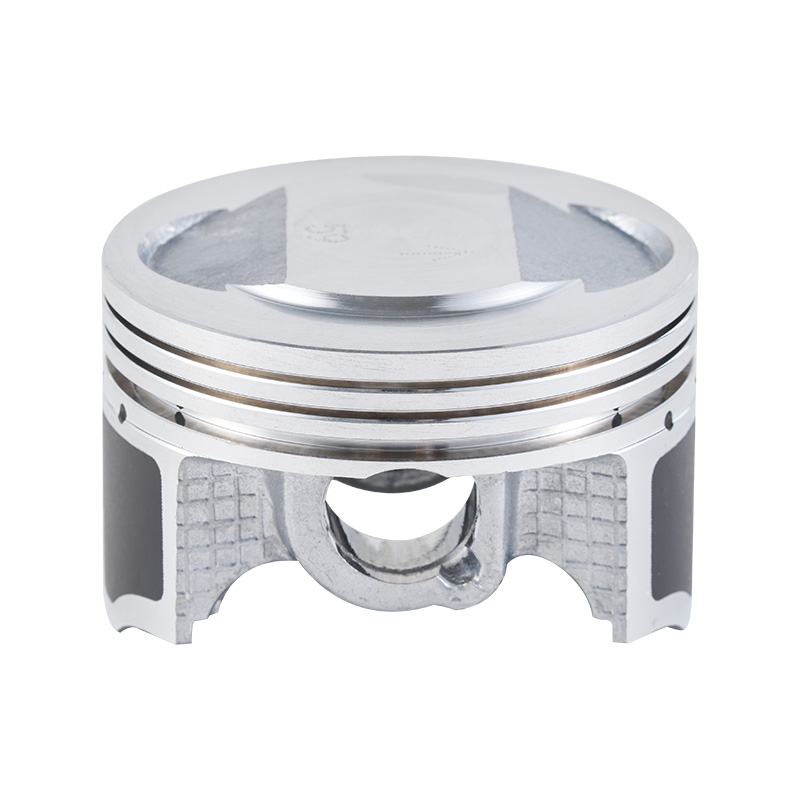

- Precision matching: Pistons and rings are engineered together to ensure good sealing, reducing blow-by and oil consumption.

- Stable combustion performance: Accurate ring tension and groove dimensions improve compression consistency across engine cycles.

- Long service life: Carefully selected aluminum alloys and wear-resistant ring materials help engines withstand high temperatures and friction.

- Wide engine coverage: Suitable for passenger cars, motorcycles, light commercial vehicles, and small industrial engines.

From factory testing to final inspection, every piston and ring set is produced with OEM-level standards, making it ideal for both replacement markets and long-term engine rebuild programs.

2) What makes Zhengji's Piston and Cylinder Kit suitable for engine rebuild projects?

A Piston and Cylinder Kit must ensure dimensional accuracy and material compatibility to restore engine performance. Zhengji's kits are designed to simplify rebuild work while improving reliability.

Product highlights:

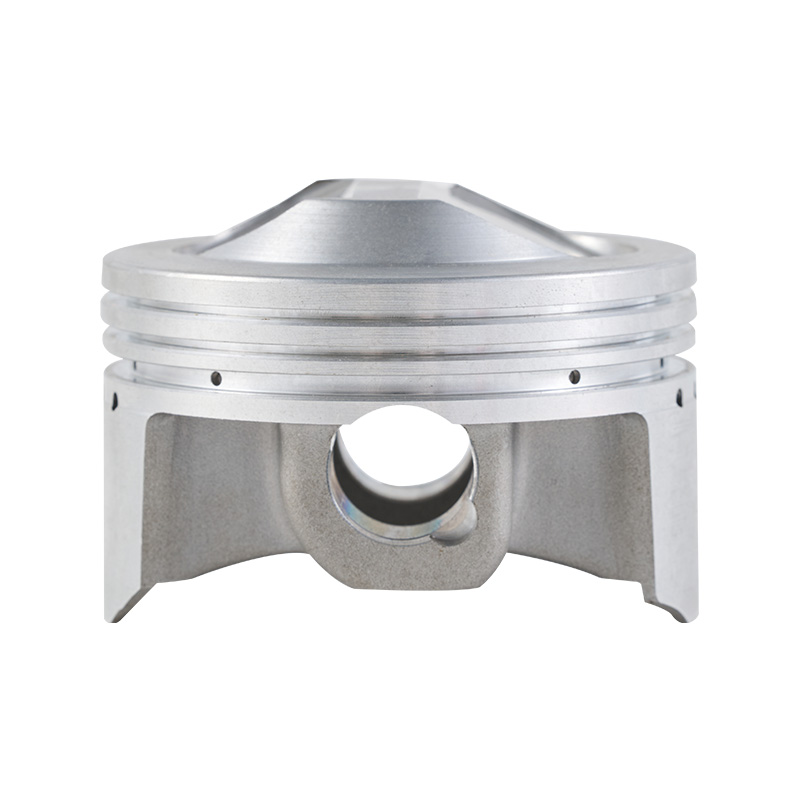

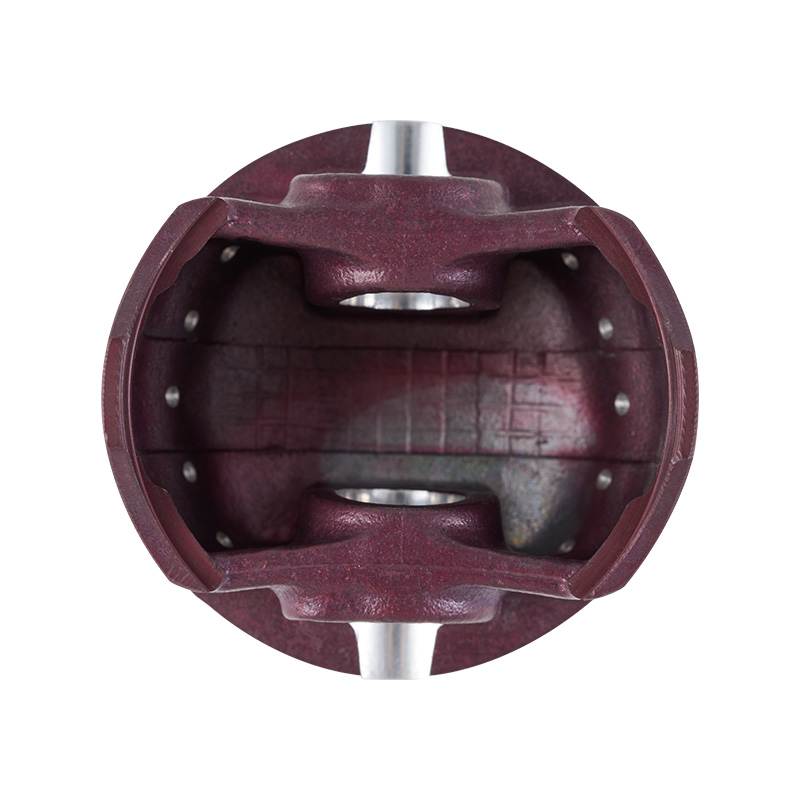

- Consistent bore matching: Cylinders and pistons are manufactured with strict tolerances to ensure smooth piston movement and proper oil film control.

- Multiple size options: Standard size and oversize kits are available to support re-boring and worn engine repairs.

- Balanced strength and weight: Optimized piston skirt design reduces vibration and noise during operation.

- Ready-to-install convenience: Each kit includes essential components, reducing sourcing complexity for workshops and distributors.

These advantages make Zhengji's piston and cylinder kits widely used in maintenance, refurbishment, and aftermarket performance upgrades.

3) How does Zhengji perform as a Professional Piston Ring Manufacturer?

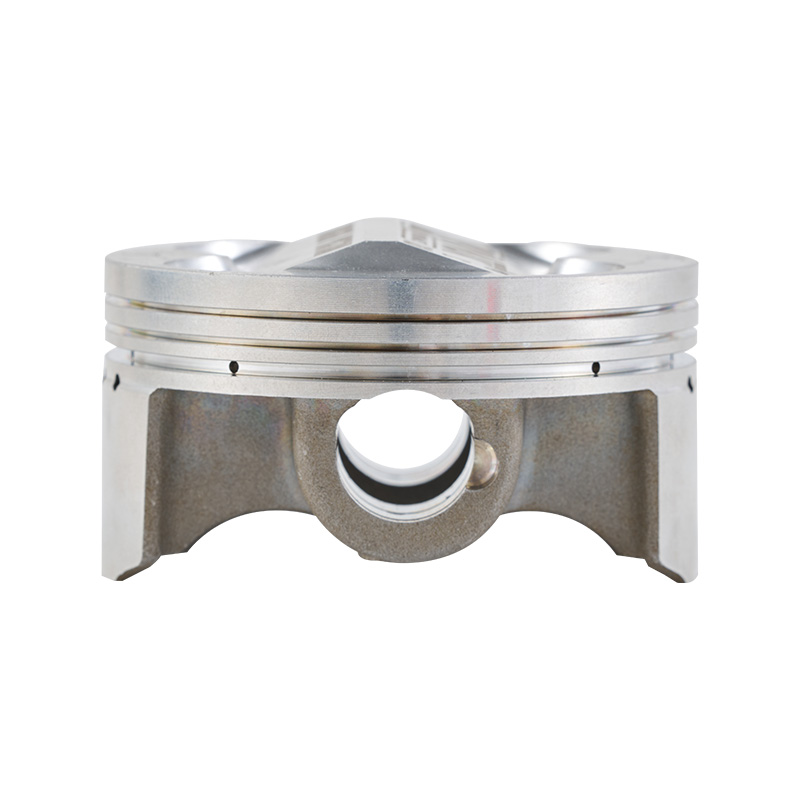

As a Professional Piston Ring Manufacturer, Zhengji focuses on ring sealing efficiency, wear resistance, and friction control—three core factors that directly affect engine lifespan.

Our piston ring strengths include:

- Advanced ring profiles: Designed to improve gas sealing while minimizing cylinder wall wear.

- Material flexibility: Different ring materials and surface treatments are available based on engine load, speed, and operating temperature.

- Stable oil control: Proper oil ring tension helps prevent excessive oil consumption and exhaust smoke.

- Compatibility assurance: Rings are engineered to goodly match piston groove geometry, ensuring consistent performance.

This professional approach allows Zhengji to serve both OEM customers and aftermarket brands seeking reliable, long-term engine solutions.

4) What OEM and private-label customization does Zhengji offer?

Zhengji understands that different markets and engine platforms require tailored solutions. Our OEM customization service covers the full development cycle.

OEM customization options include:

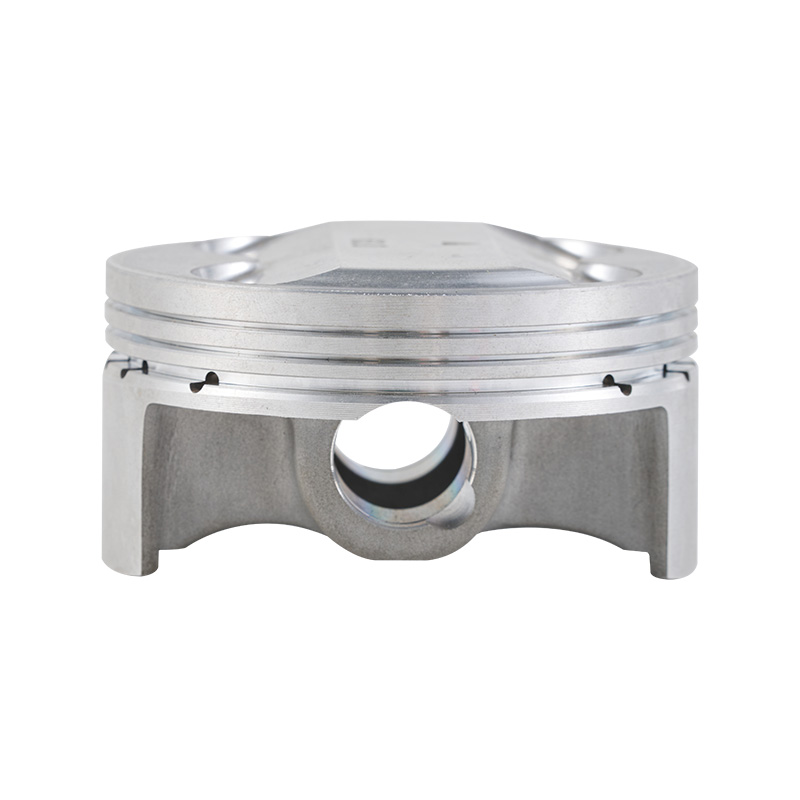

- Piston design customization: Crown shape, compression height, skirt profile, and pin size adjustments.

- Ring configuration customization: Ring thickness, tension levels, and material selection based on application needs.

- Branding support: Custom markings, packaging, and private-label options for distributors and wholesalers.

- Technical support: Engineering assistance from sample analysis to mass production approval.

This flexibility allows customers to build differentiated product lines while maintaining consistent quality across batches.

5) How does Zhengji ensure quality consistency across automotive car parts production?

Quality consistency is the foundation of Zhengji's manufacturing philosophy in automotive car parts.

Our quality control system includes:

- In-house production control: From casting to machining and inspection, key processes are managed internally.

- Precision testing equipment: Dimensional, hardness, and surface finish inspections ensure every component meets specifications.

- Batch traceability: Each production batch is recorded for material and process accountability.

- Export-oriented standards: Products are manufactured to meet the expectations of global markets and professional repair industries.

As a result, Zhengji's piston and ring products deliver stable performance, reduced failure rates, and strong market confidence.

Français

Français 中文简体

中文简体 Español

Español