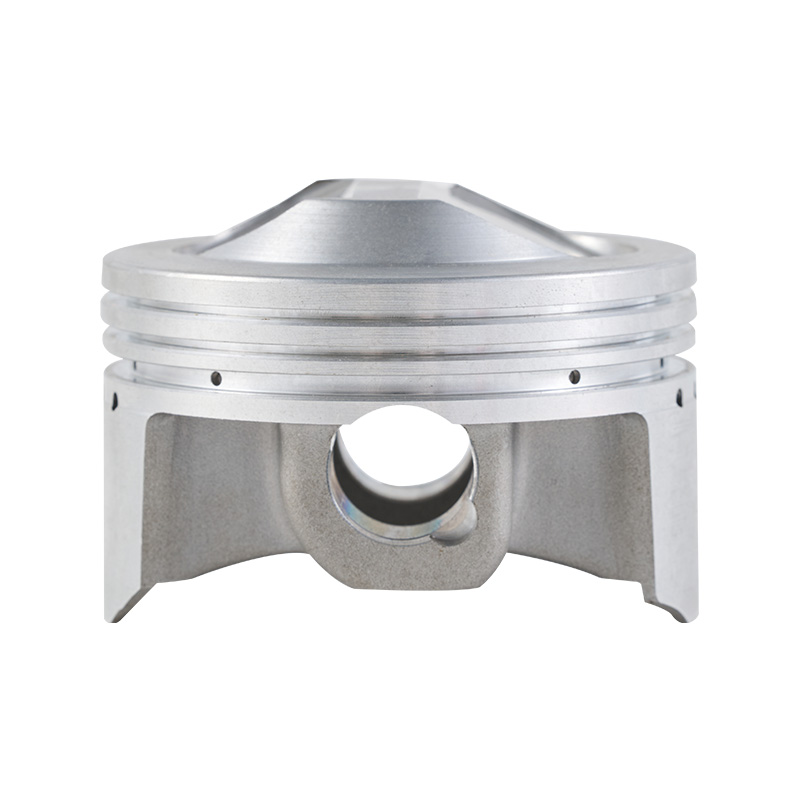

New Material Pistons: An Innovative Force for Leapfrog Performance Improvements

Author: Zhengji

Date: Sep 12, 2025

With the continuous advancement of technology, the application of new materials in piston manufacturing has brought about significant enhancements and improvements to piston performance.

◆ Optimization and Improvement of Materials

Through in-depth analysis of the structure and performance of traditional aluminum-silicon alloys, and the optimization of modification treatment processes, the performance of piston materials can be effectively improved, the occurrence of fatigue cracks can be reduced, and the service life of pistons can be extended.

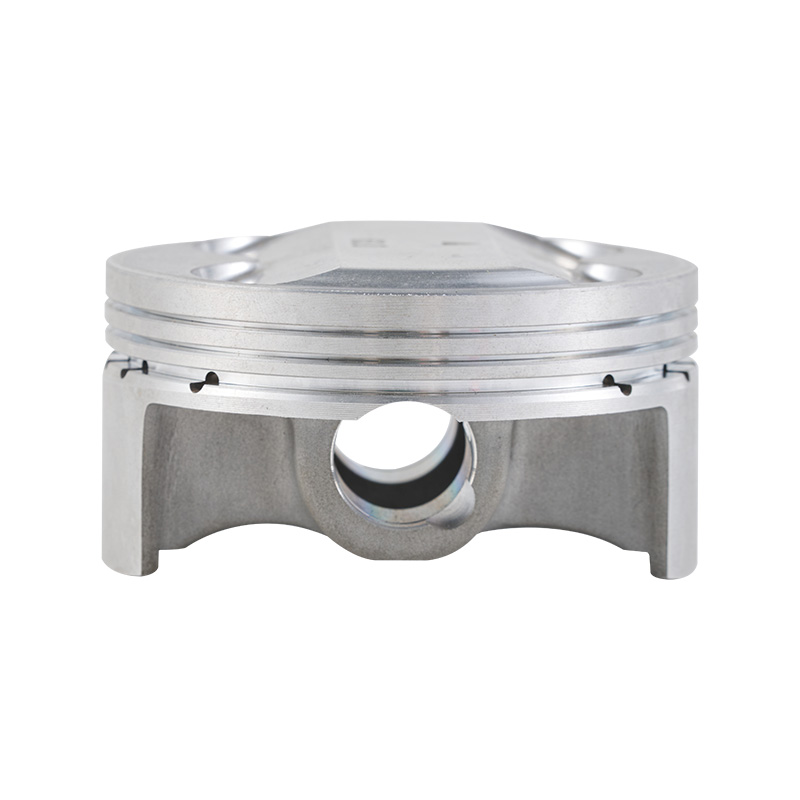

As a new type of piston material, ceramic matrix composites (CMCs) possess outstanding high-temperature stability, wear resistance, and lightweight advantages. Their application in piston manufacturing can greatly enhance the piston’s heat resistance and wear resistance while reducing piston mass—further improving fuel economy and providing strong support for the efficient operation of engines.

High-temperature alloys, with their excellent high-temperature resistance and oxidation resistance, can maintain stable mechanical properties in high-temperature environments, making them particularly suitable for manufacturing pistons in engines operating under high-temperature conditions.

High-strength steel, as a piston material, boasts exceptional mechanical properties and fatigue life. Using high-strength steel to manufacture pistons not only improves the piston’s strength and rigidity but also reduces its size and weight, which helps increase the engine’s power density and fuel economy.

In addition, the addition of nanomaterials has opened up a new avenue for improving the performance of piston materials. It can not only enhance the material’s mechanical properties and wear resistance but also optimize tribological (friction-related) and thermal conductivity performance—thereby improving the overall efficiency and service life of the engine.

Pistons made of new materials have achieved remarkable improvements in power output, energy conservation and consumption reduction, and material performance. They have brought new opportunities and transformations to the development of related fields such as automotive and industrial sectors.

Français

Français 中文简体

中文简体 Español

Español