The Piston: Core Component of Automobile Engine Power

In the heart of every modern internal combustion engine lies a small but mighty part—the Automobile Engine Piston. Though compact in size compared to larger structures like the cylinder block or crankshaft, this component plays a defining role in converting chemical energy from fuel into mechanical power that drives vehicles.

As a professional manufacturer and supplier of automobile engine parts, Zhengji has extensive experience in designing and optimizing pistons and related automobile engine components for enhanced performance, durability, and efficiency.

1. What Is the Role of an Automobile Engine Piston?

At its core, the Automobile Engine Piston functions as a movable plug inside the cylinder, converting the rapid pressure rise from combustion into reciprocating mechanical motion. This motion is ultimately transmitted through connecting rods and the crankshaft to generate rotational power used to propel the vehicle. The repeating up-and-down movement of the piston forms the basis of the engine's four-stroke cycle—intake, compression, power, and exhaust—making it an indispensable member of the automobile engine parts family.

The piston's contribution to power generation cannot be overstated. A well-engineered piston ensures efficient compression of the air-fuel mixture, improves combustion pressure, and sustains structural integrity under thermal and mechanical stress. Because the piston directly interacts with combustion gases, its material properties, geometry, and surface quality are critical. High-performance pistons not only boost engine output but also enhance fuel economy and reduce emissions.

2. How Is the Automobile Engine Piston Constructed?

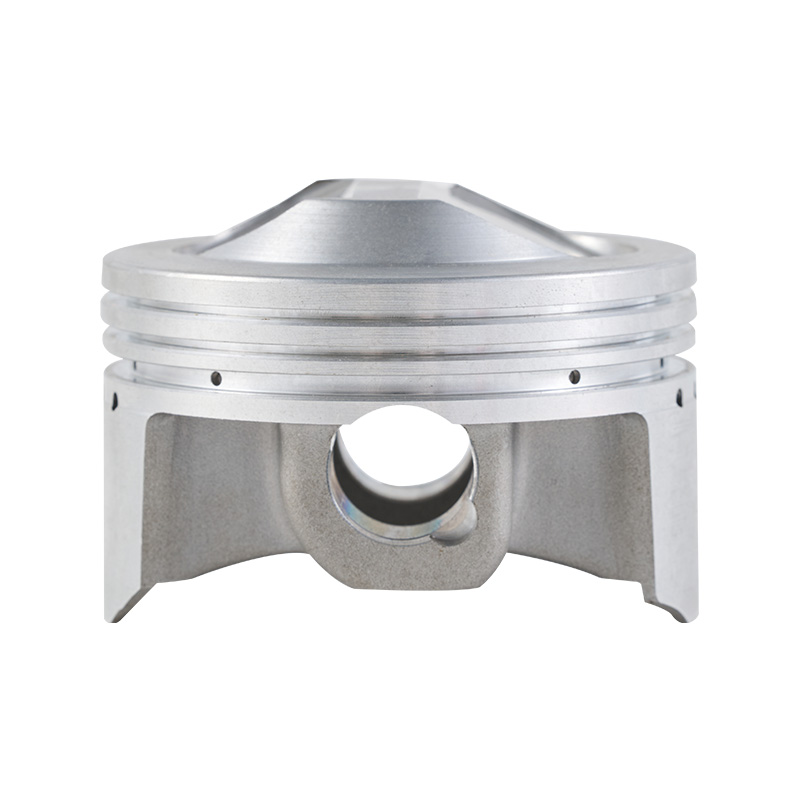

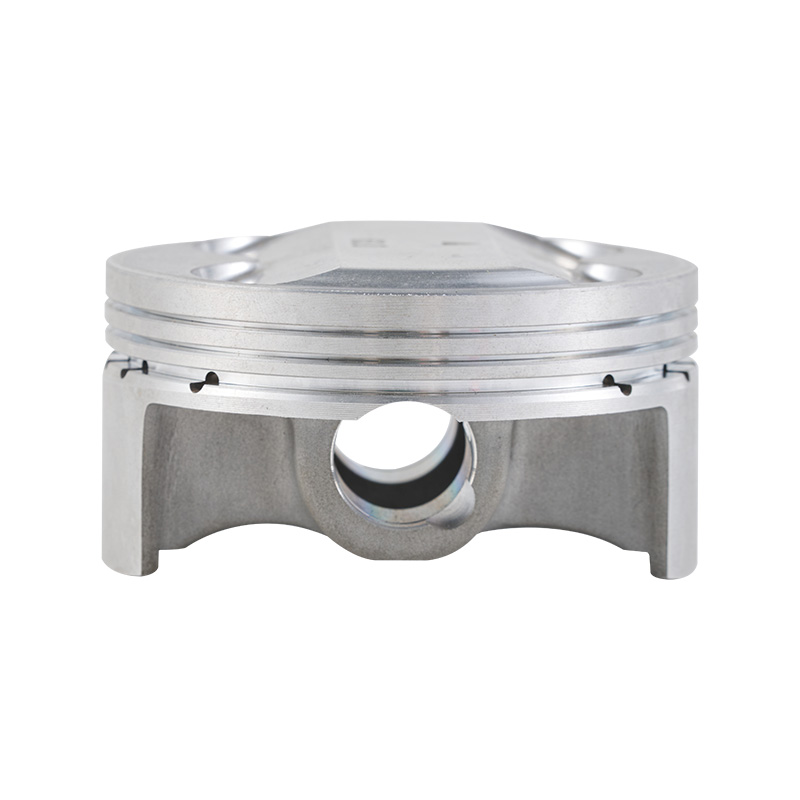

An Automobile Engine Piston is more than a simple metal cylinder; it is a finely tuned automobile engine component composed of multiple integrated features designed to work in a hostile environment.

Major structural elements include:

- Piston Crown: The top surface which houses the combustion chamber geometry. Its shape influences combustion efficiency and determines the compression ratio.

- Piston Skirt: The lower portion that maintains lateral stability within the cylinder.

- Ring Grooves and Rings: Precision-engineered slots for piston rings that seal combustion gases and control oil distribution.

- Piston Pin Boss: The reinforced area where the connecting rod attaches, transmitting force to the crankshaft.

The interaction between the piston and related automobile engine parts like rings and the cylinder liner must be seamless to maintain tight seals while minimizing friction. Poor design or mismatched components can result in power loss, increased wear, and reduced fuel efficiency.

3. What Materials Are Used in Piston Manufacturing?

Historically, aluminum alloys have been the predominant choice for Automobile Engine Pistons due to their favorable strength-to-weight ratio and thermal conductivity. Aluminum's low density helps reduce reciprocating mass, allowing engines to rev higher with reduced inertia. However, for heavy-duty or high-performance applications, advanced materials and surface treatments are sometimes applied to further enhance thermal stability and wear resistance.

In select cases, steel or cast components may be used depending on engine type and operating conditions. Whatever the material, precision forging and machining are required to produce pistons that meet stringent tolerances and functional standards within the broader set of automobile engine parts.

4. How Does the Piston Work With Other Engine Components?

The Automobile Engine Piston is one among many automobile engine components that must operate in precise harmony. It functions within a coordinated system that includes the cylinder block, crankshaft, connecting rods, camshaft, valves, and timing mechanisms. In each combustion cycle:

- Intake Stroke: The piston moves downward, drawing in air-fuel mixture.

- Compression Stroke: The piston compresses the mixture as it ascends.

- Combustion/Power Stroke: Fuel ignites, forcing the piston downward with high pressure.

- Exhaust Stroke: The piston rises again to expel combustion gases.

Each stroke depends on the piston's precise motion and synergy with other components like the cylinder wall and crankshaft. Any imbalance or misalignment in the piston assembly can cause inefficiencies or mechanical stress, affecting performance and service life of the entire automobile engine parts package.

5. What Challenges Do Pistons Face in Engine Operation?

The Automobile Engine Piston operates in one of challenging environments within the engine. Combustion pressures can exceed thousands of pounds per square inch, and temperatures frequently rise well above 200°C (392°F). Alongside this thermal assault, pistons endure rapid acceleration and deceleration, sliding within the cylinder under heavy loads.

These conditions demand that the piston maintains structural integrity while minimizing friction against the cylinder wall. Optimized piston design and high-quality materials are essential to prevent deformation, scuffing, or eventual failure—issues that accelerate wear in other automobile engine components and reduce overall engine reliability.

6. How Do Pistons Influence Fuel Efficiency and Emissions?

Because the piston plays a direct role in compressing the air-fuel mixture and maintaining combustion chamber sealing, its design directly affects fuel efficiency and emissions. A piston that preserves good compression will improve thermal efficiency, resulting in better fuel economy and cleaner combustion. Furthermore, precision piston and ring geometries reduce blow-by gases—combustion gases that escape past rings—which lowers hydrocarbon emissions and helps meet stringent environmental standards.

Innovations in piston design—such as optimized crown shapes, improved ring configurations, and advanced coatings—have significantly contributed to lower emissions and higher efficiency in modern engines. These improvements enhance not only performance but also meet evolving regulatory demands for cleaner engines.

7. How Is Piston Technology Evolving?

Today's Automobile Engine Pistons are evolving in response to the global push for more efficient, lighter, and cleaner engines. Advanced manufacturing technologies like high-pressure die casting, precision forging, and surface treatments reduce weight while maintaining strength.

Emerging trends also include the use of coatings that reduce friction and enhance heat resistance, as well as experimental use of additive manufacturing for highly customized piston geometries in performance applications. These technologies aim to squeeze more power from smaller displacements while reducing emissions—critical as global automotive markets trend toward downsized engines with turbocharging and direct injection.

8. Why Quality Matters in Piston Production

When it comes to automobile engine parts, quality is paramount. A poorly manufactured piston can cause rapid wear, oil consumption, increased vibration, and even catastrophic engine failure. This risk underscores the importance of precision engineering in piston manufacturing, coupled with rigorous testing and quality assurance at every stage.

Zhengji understands this requirement. By applying advanced machining technologies, surface treatments, and rigorous inspection protocols, each Automobile Engine Piston produced meets or exceeds global standards for reliability and performance. Additionally, integrating pistons with matched automobile engine components ensures compatibility and longer service life in diverse operating environments.

9. How Do Pistons Fit into the Broader Engine Assembly?

An engine consists of dozens of automobile engine parts, but the piston is fundamental to power generation. A complete engine assembly includes pistons, rings, connecting rods, crankshaft, cylinder head, valvetrain, and numerous ancillary components. Each part must work flawlessly with the piston to convert fuel into usable mechanical energy.

At Zhengji, product development emphasizes system-level integration, not just individual part performance. This approach ensures that pistons and rings engage smoothly with cylinder walls, minimizing friction and extending service life for all automobile engine components.

10. The Broader Impact of Pistons in Automotive Engineering

Beyond power and efficiency, pistons influence the feel of the drive, noise characteristics, and thermal behavior of the engine. Well-designed pistons contribute to a smoother idle, reduced engine noise, and better responsiveness under load—all critical considerations for automotive engineers seeking to balance performance and comfort.

With continuous advancements in materials science and manufacturing, pistons remain at the forefront of engine evolution. Whether in standard passenger vehicles, heavy-duty commercial engines, or high-performance automobiles, the piston's role is central to the future of internal combustion powertrains.

The Automobile Engine Piston remains one of vital automobile engine parts in internal combustion engines. Its interaction with other automobile engine components like rings, connecting rods, and cylinder walls determines power output, efficiency, and long-term reliability. From material selection to structural design and surface finish, every aspect of piston production influences overall engine performance.

Français

Français 中文简体

中文简体 Español

Español