Optimizing Engines with Custom High-Performance Pistons

For automotive enthusiasts and professional builders, the piston is more than a simple metal cylinder—it's a critical engine component that directly affects power, efficiency, and durability. Among the wide range of options, custom forged pistons, custom cast pistons, and custom billet pistons stand out as top choices for high-performance or highly specific applications.

Each type brings unique advantages, manufacturing processes, and ideal uses, and understanding these differences is key to selecting the right custom piston for your engine.

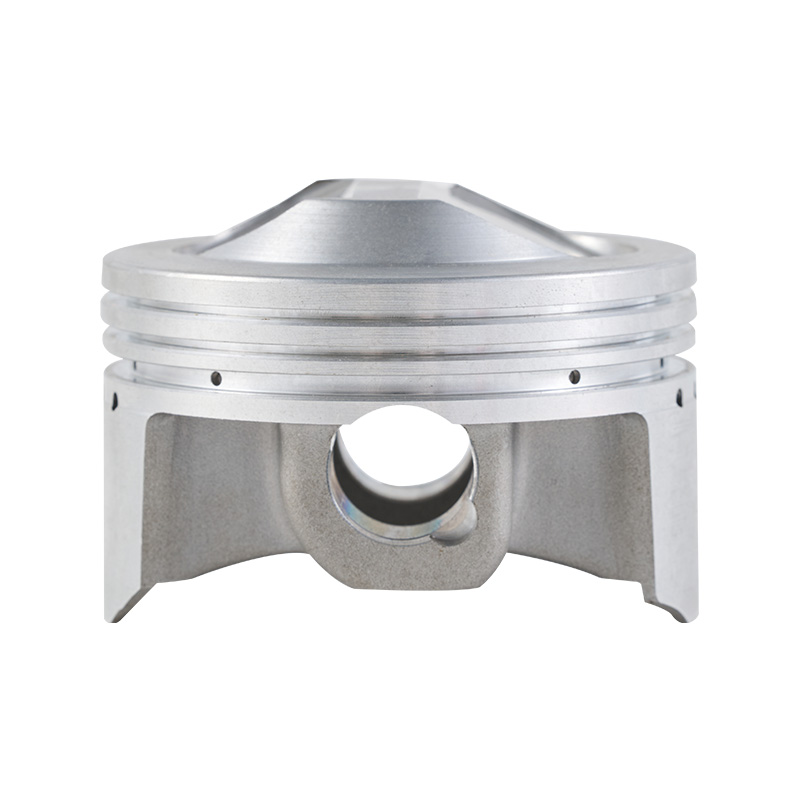

1. What Are Custom Forged Pistons?

Custom forged pistons are manufactured by compressing high-quality aluminum alloy billets under pressure. This forging process aligns the metal grains, producing a dense, strong structure capable of withstanding high combustion pressures and temperatures.

Key features of custom forged pistons include:

- Enhanced strength and durability: Ideal for high-performance and racing engines.

- Reduced risk of cracking or deformation: Critical under high RPM and turbocharged conditions.

- Compatibility with other engine components: Works well with reinforced connecting rods and high-performance crankshafts.

Enthusiasts often choose custom forged pistons when durability and reliability under conditions are top priorities. Unlike cast alternatives, forged pistons resist fatigue and can tolerate aggressive tuning without compromising engine safety.

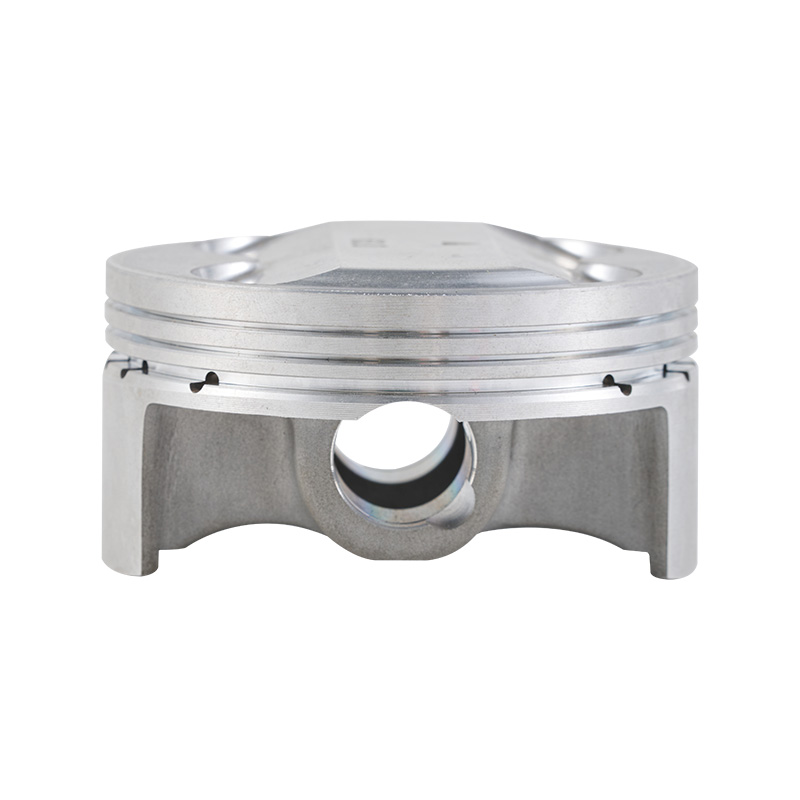

2. Understanding Custom Cast Pistons

Custom cast pistons are produced by pouring molten aluminum into precise molds. This method allows for more complex geometries and cost-effective manufacturing for medium to high-performance engines.

Advantages of custom cast pistons include:

- Complex shapes and integrated features: Enables optimized combustion chamber designs.

- Cost-effective production: Suitable for performance upgrades without budget requirements.

- Smooth surface finish: Reduces initial friction when fitted with other engine components.

While custom cast pistons may not match forged pistons in raw strength, they are ideal for naturally aspirated engines, street performance builds, and moderate tuning applications. They integrate well with standard engine components, providing a balanced combination of performance and affordability.

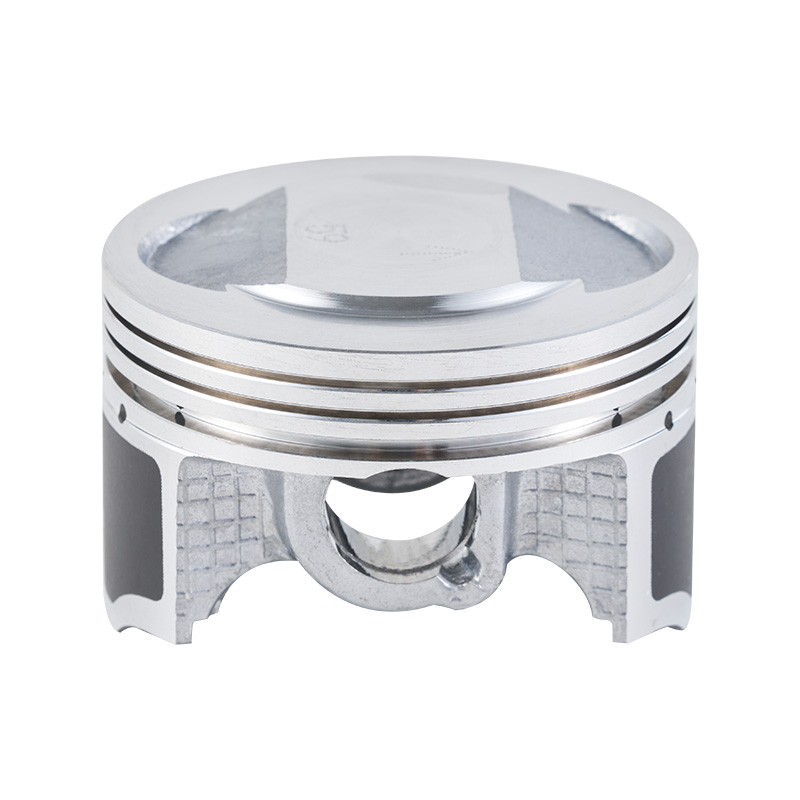

3. What Makes Custom Billet Pistons Unique?

Custom billet pistons are CNC-machined from solid aluminum blocks. This method allows engineers to create highly precise, one-off pistons tailored to specific engine requirements.

Key benefits of custom billet pistons include:

- Good precision: Every dimension is carefully controlled to optimize clearance, compression, and weight.

- Unlimited customization: Engineers can tailor crown shape, skirt design, and ring grooves to any engine specification.

- Performance advantage: Especially useful for specialized racing, drag, or turbocharged applications.

Billet pistons are often the choice for high-end engine builds, where every fraction of a gram and millimeter contributes to performance. Combined with other high-performance engine components, custom billet pistons enable maximal power, response, and efficiency.

4. Comparing Forged, Cast, and Billet Pistons

Each piston type is suited for different goals. Here's a comparative overview:

| Feature | Custom Forged Pistons | Custom Cast Pistons | Custom Billet Pistons |

| Strength | Very high | Moderate | Very high |

| Cost | Moderate | Lower | High |

| Weight | Lightweight | Slightly heavier | Tunable |

| Application | Racing, turbocharged, high stress | Street, mild tuning | Custom builds, performance |

| Customization | Limited to size/shape | Moderate | Unlimited |

This table highlights how custom forged pistons, custom cast pistons, and custom billet pistons fit different engine performance objectives and budgets. Choosing the right piston type requires evaluating the overall engine build, engine components compatibility, and performance goals.

5. How Pistons Integrate With Engine Components

Regardless of type, custom forged pistons, custom cast pistons, and custom billet pistons function as central engine components in a system of interdependent parts. Proper integration includes:

- Piston-to-cylinder fit: Ensures minimal friction and proper sealing with the rings.

- Connecting rod and crankshaft compatibility: Forged pistons often pair with reinforced rods; billet pistons can be designed for exact rod alignment.

- Lubrication and cooling: Well-designed pistons maintain good oil flow, minimizing wear on adjacent engine components.

Selecting high-quality custom pistons ensures that the engine system remains balanced, responsive, and durable, even under high loads or operating conditions.

6. Material Considerations

The material choice influences piston performance across all types.

- Custom forged pistons use high-strength aluminum alloys for heat resistance and durability.

- Custom cast pistons rely on standard aluminum or silicon-aluminum alloys to balance cost and strength.

- Custom billet pistons can use premium aluminum alloys and surface coatings for friction reduction and thermal efficiency.

Advanced coatings and treatments enhance all piston types, reducing wear on both the pistons themselves and adjacent engine components.

7. Performance Benefits for Engine Builds

Incorporating custom forged pistons, custom cast pistons, or custom billet pistons improves overall engine performance. Key benefits include:

- Higher compression ratios: causing improved power and efficiency.

- Reduced weight and inertia: Allows faster engine response and higher RPM stability.

- Extended durability: Especially for forged and billet pistons, which withstand long-term stress.

- Customization: Tailoring piston geometry for specific engine builds, including turbocharging, supercharging, or naturally aspirated setups.

Integrating these pistons with compatible engine components improves the synergy between parts, resulting in smoother, more reliable, and higher-performing engines.

8. Applications Across Vehicle Types

Custom forged pistons, custom cast pistons, and custom billet pistons are used across a wide range of vehicles:

| Vehicle Type | Recommended Piston Type | Notes |

| Racing cars | Forged / Billet | High stress, high RPM |

| Street performance | Cast / Forged | Balanced power and cost |

| Custom builds | Billet | Unique engine configurations |

| Off-road vehicles | Forged | Durability under heavy load |

Proper selection ensures that pistons perform well while interacting seamlessly with other engine components.

9. Future Trends in Piston Technology

Piston design continues to evolve:

- Lightweight alloys to reduce reciprocating mass.

- Surface coatings for improved thermal efficiency and reduced friction.

- Precision CNC machining for fully customized custom billet pistons.

- Integration with modern engine tech such as turbocharging, direct injection, and hybrid systems.

These advancements highlight the importance of choosing the right piston type for both performance and longevity in modern engines.

10. Conclusion

Selecting the right custom forged pistons, custom cast pistons, or custom billet pistons is essential for fully unlocking engine potential and achieving stable, long-term performance gains. Proper selection directly affects combustion efficiency, mechanical strength, thermal resistance, and overall reliability.

Each piston type offers unique benefits—forged pistons provide exceptional strength and reliability under conditions, cast pistons balance cost with versatility and moderate performance, and billet pistons deliver high quality precision and customization for specialized builds.

When combined with complementary engine components, these pistons ensure good combustion efficiency, reduced wear, and smoother power delivery.

For performance enthusiasts, OEM builders, and professional tuners, investing in high-quality custom forged pistons, custom cast pistons, or custom billet pistons guarantees long-term durability, improved fuel efficiency, and a outstanding driving or riding experience.

The piston is not just a component—it is the heartbeat of the engine, and selecting the right type is a decisive factor in achieving peak performance and reliability.

Français

Français 中文简体

中文简体 Español

Español