Unlocking Power with Custom Motorcycle Pistons

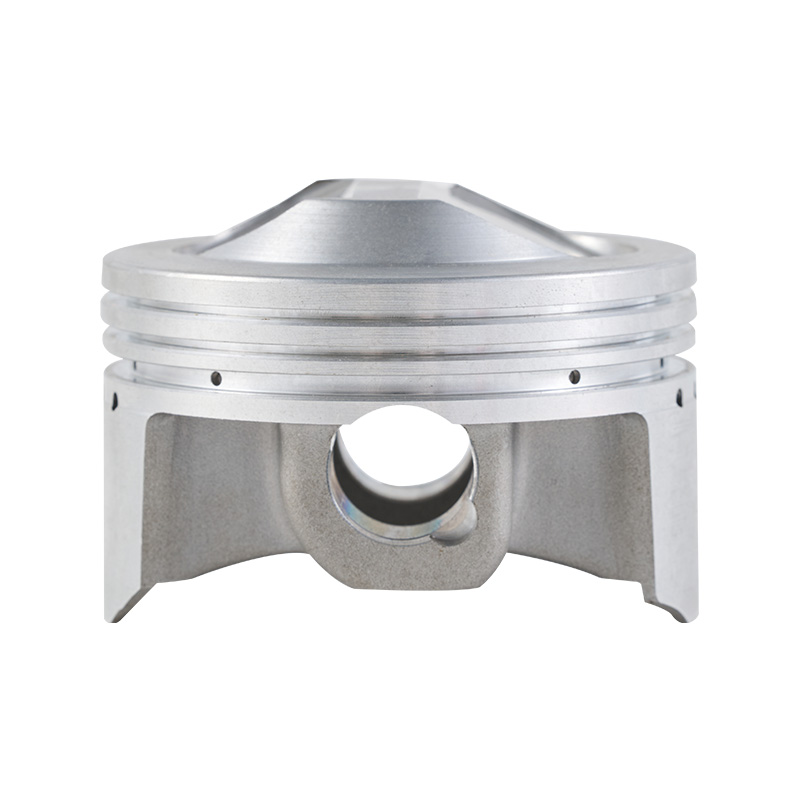

Modern motorcycles are more than just transportation—they are precision machines where performance, reliability, and longevity are determined by critical components. Among these, custom motorcycle pistons and forged motorcycle pistons play pivotal roles in defining engine efficiency, power output, and durability. In conjunction with other motorcycle engine parts, these pistons are central to the rider's experience, whether on a high-speed track, rugged terrain, or daily commuting.

This article explores the design, application, and advantages of custom motorcycle pistons, the evolution and benefits of forged motorcycle pistons, and the importance of compatible motorcycle engine parts.

1. The Role of Custom Motorcycle Pistons

A custom motorcycle piston is designed specifically to match the performance requirements, engine configuration, and riding style of a motorcycle. Unlike standard pistons, these are tailored to:

- Achieve good compression ratios for different engine types

- improve combustion efficiency for better power delivery

- Fit seamlessly with other motorcycle engine parts such as cylinders, rings, and connecting rods

Motorcycle enthusiasts and manufacturers often choose custom motorcycle pistons to improve throttle response, increase top-end power, or fine-tune low-end torque. For instance, touring bikes may prioritize smoothness and longevity, while racing motorcycles focus on peak horsepower and engine stability at high RPMs.

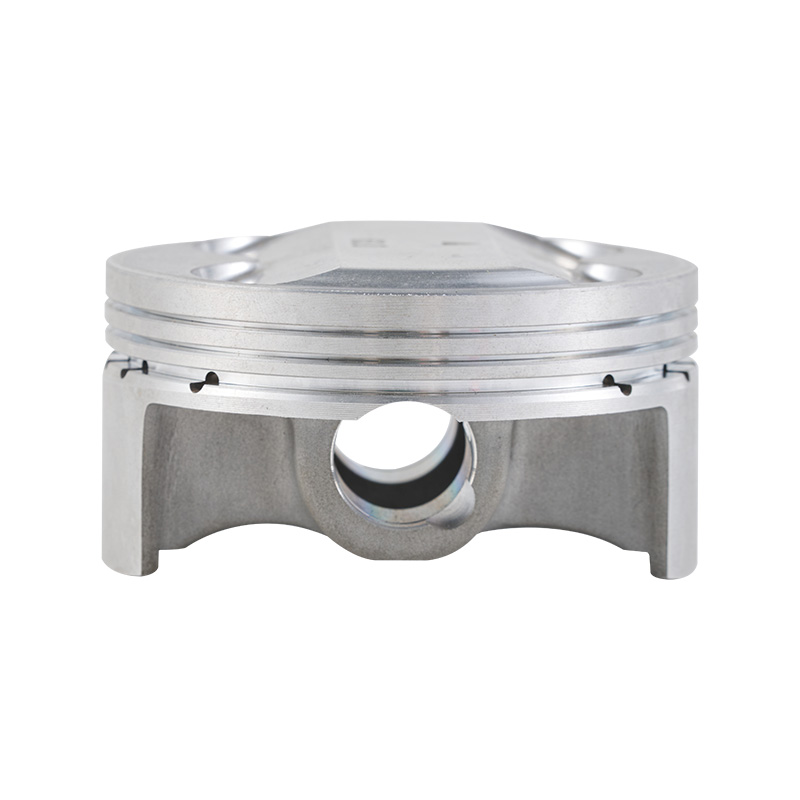

2. Advantages of Forged Motorcycle Pistons

Forged motorcycle pistons are manufactured under high pressure to create a dense, strong structure. This process produces several advantages over cast alternatives:

- Enhanced strength: Forged pistons can withstand higher combustion pressures and temperatures, critical in high-performance motorcycles.

- Durability under stress: These pistons are less likely to crack or deform during conditions, extending engine lifespan.

- Consistent performance: Reduced thermal expansion ensures tighter tolerances and stable operation with other motorcycle engine parts.

Motorcycle racers and custom bike builders often prefer forged motorcycle pistons because they can push the engine closer to its limits without sacrificing reliability. Additionally, when paired with compatible motorcycle engine parts, these pistons create a cohesive system optimized for improve performance.

3. How Motorcycle Engine Parts Work Together

The piston is just one element in a complex ecosystem of motorcycle engine parts. Proper coordination between pistons, cylinder heads, valves, crankshafts, and camshafts determines overall engine efficiency and longevity.

Key interactions include:

- Piston-to-cylinder fit: Ensures minimal friction and good sealing. Custom motorcycle pistons can be tailored to specific bore tolerances.

- Connection to rods and crankshaft: Forged motorcycle pistons maintain structural integrity, reducing stress on connecting rods.

- Thermal and lubrication management: Quality motorcycle engine parts support heat dissipation and consistent oil flow to prevent wear and maintain smooth operation.

By designing custom motorcycle pistons with matching motorcycle engine parts, engineers can optimize the engine for high RPM performance or extended touring reliability.

4. Material Selection and Manufacturing Techniques

The materials and manufacturing processes for custom motorcycle pistons are critical to performance. High-grade aluminum alloys are often used for lightweight applications, while forged pistons may include additional treatments to improve heat resistance and surface hardness.

- Forged motorcycle pistons offer outstanding mechanical strength and fatigue resistance.

- Custom motorcycle pistons allow tuning of alloy composition, crown design, and skirt shape to match riding demands.

- Compatibility with motorcycle engine parts ensures uniform wear and consistent power output.

Advances in CNC machining, forging techniques, and coatings further enhance piston performance, creating a synergy between custom motorcycle pistons, forged motorcycle pistons, and other essential motorcycle engine parts.

5. Performance Benefits for Riders

Integrating custom motorcycle pistons and forged motorcycle pistons with optimized motorcycle engine parts delivers tangible benefits for riders:

- Improved throttle response: Engine reacts quickly to rider input due to precise piston fit and light weight.

- Increased power and torque: Optimized combustion dynamics from custom pistons enhance performance.

- Extended engine life: Forged pistons resist deformation, reducing wear on cylinders and other motorcycle engine parts.

- Enhanced fuel efficiency: Better sealing and combustion control reduce fuel waste and emissions.

Motorcycle riders often report smoother acceleration, less engine vibration, and higher confidence during aggressive riding when their bike uses high-quality custom motorcycle pistons or forged motorcycle pistons.

6. Applications Across Motorcycle Types

Custom motorcycle pistons and forged motorcycle pistons are not limited to racing bikes. Their applications span a wide range of motorcycles:

| Motorcycle Type | Recommended Pistons | Supporting Motorcycle Engine Parts |

| Sport Bikes | Forged motorcycle pistons | High-performance camshafts, lightweight rods |

| Touring Bikes | Custom motorcycle pistons | Durable cylinder heads, robust crankshafts |

| Off-Road Bikes | Forged motorcycle pistons | Reinforced engine components, heavy-duty valves |

| Daily Commuters | Custom motorcycle pistons | Standard motorcycle engine parts for longevity |

The choice of piston type, combined with compatible motorcycle engine parts, ensures that the bike performs goodly under the intended riding conditions.

7. OEM vs Aftermarket Considerations

Manufacturers and custom builders rely on custom motorcycle pistons to meet unique specifications, while forged motorcycle pistons are often preferred in aftermarket upgrades for increased durability and power. The integration of these pistons with other motorcycle engine parts must be carefully managed to maintain engine balance, reliability, and compliance with manufacturer tolerances.

8. Future Trends in Motorcycle Piston Technology

As motorcycles evolve, piston design is increasingly influenced by:

- Lightweight materials: Reducing reciprocating mass for higher RPM performance

- Advanced coatings: Minimizing friction and enhancing thermal efficiency

- Precision manufacturing: CNC and forging advancements improve tolerances and durability

- Integrated engine systems: Piston design tailored to interact with next-generation motorcycle engine parts such as variable valve timing and turbocharging

These trends emphasize the continued importance of custom motorcycle pistons and forged motorcycle pistons in high-performance and efficient motorcycle engines.

9. Conclusion

Pistons are at the heart of every motorcycle engine, and their quality directly affects performance, reliability, and rider satisfaction. Whether through custom motorcycle pistons designed for specific riding styles or forged motorcycle pistons engineered for high-stress applications, these components remain central to good engine function. Properly integrated with compatible motorcycle engine parts, they ensure smooth operation, longevity, and peak performance.

Investing in quality pistons and understanding their interaction with the rest of the motorcycle engine components is essential for enthusiasts, professional racers, and OEM manufacturers alike. As engine technologies advance, the synergy between custom motorcycle pistons, forged motorcycle pistons, and supporting motorcycle engine parts will continue to drive performance, efficiency, and innovation in the world of motorcycles.

Beyond performance and durability, custom motorcycle pistons and forged motorcycle pistons also contribute to engine customization for unique riding preferences. By combining these high-quality pistons with optimized motorcycle engine parts, builders can achieve precise tuning, smoother acceleration, and reduced vibration. Riders benefit from enhanced responsiveness and reliability, whether on city streets or challenging terrains. Investing in carefully designed custom motorcycle pistons and complementary forged motorcycle pistons ensures that the engine operates efficiently, prolongs the life of motorcycle engine parts, and delivers a outstanding riding experience.

Français

Français 中文简体

中文简体 Español

Español