The Piston's Wide-Ranging Application Fields: A Key Driver of Industrial Operation

Author: Zhengji

Date: Sep 09, 2025

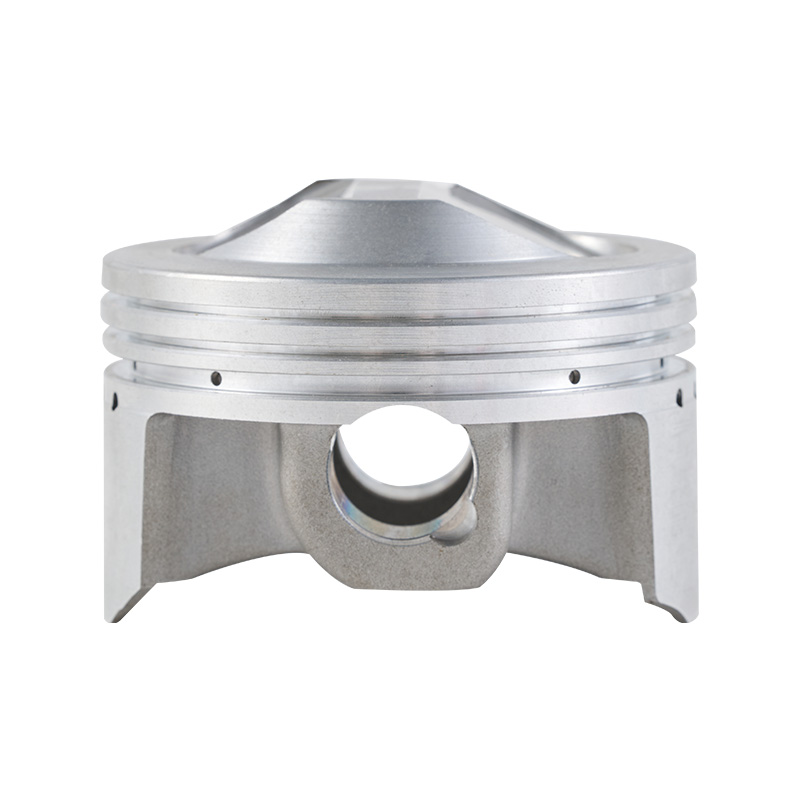

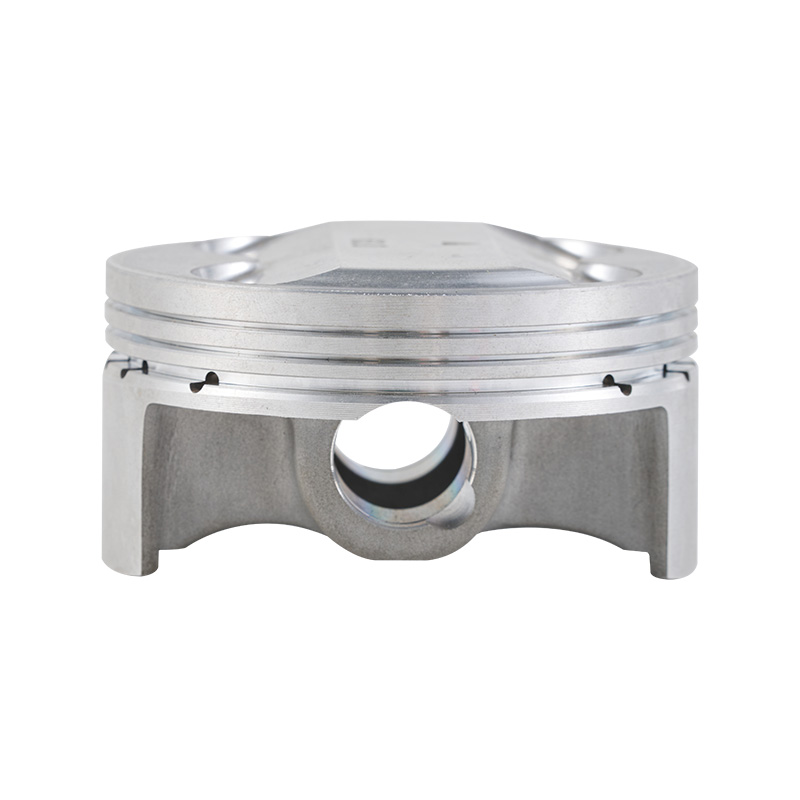

In the bustling industrial world, the piston is a seemingly small yet crucial component. Its application fields are extremely broad, covering nearly all mechanical equipment that requires gas compression or discharge.

◆ Automotive Industry

In the automotive industry, the piston is one of the most core components in the engine, and its performance directly affects the engine's power, fuel economy, and reliability. Different types of automotive engines, such as gasoline engines and diesel engines, have different design requirements for pistons. High-performance engines demand pistons with better heat resistance, wear resistance, and lightweight properties to adapt to high-speed and high-load operating conditions, thereby improving fuel efficiency and power output.

◆ Petrochemical Industry

In the petrochemical industry, piston compressors are widely used for gas compression and transportation, providing a stable gas source for various process operations. These compressors need to operate in environments with high pressure, high temperature, and complex chemical media. Therefore, they have extremely high requirements for the piston's material, sealing performance, and compressive strength. Reliable piston performance ensures the continuity and safety of chemical production processes.

◆ Other Fields

Additionally, in the refrigeration and air conditioning sector, piston compressors are used to compress refrigerants, enabling heat transfer and creating a comfortable living and working environment for people. In the metallurgical industry, pistons are applied in some gas compression equipment to provide the necessary gas conditions for metal smelting processes. In the power industry, some power generation equipment also uses pistons to facilitate the efficient conversion of energy. With its diverse designs and reliable performance, the piston plays an irreplaceable role in various industrial fields, driving the continuous operation of industry.

Français

Français 中文简体

中文简体 Español

Español