High-Performance Forged Piston Modification Parts - Industry Knowledge Extension

1) Why are Forged Piston Modification Parts essential for serious engine upgrades?

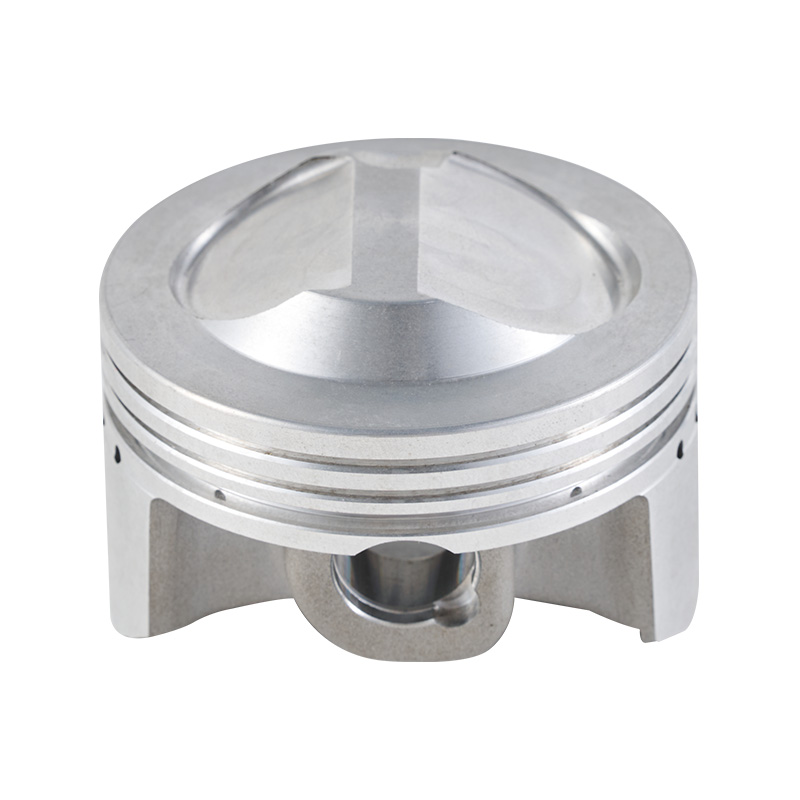

In performance-focused engine builds, Forged Piston Modification Parts are not optional components—they are structural upgrades. Compared with standard cast pistons, forged solutions are designed to survive higher cylinder pressure, combustion temperatures, and aggressive tuning strategies.

From Zhengji's manufacturing perspective, Forged Piston Modification Parts are especially critical when engines operate beyond factory limits. These parts are commonly applied in turbocharged, supercharged, or high-compression builds where stock pistons may deform or crack. By using controlled forging pistons processes, internal grain structure becomes denser and more uniform, directly improving fatigue resistance.

Unlike basic replacement performance pistons, forged modification parts allow deeper customization in crown thickness, skirt reinforcement, and pin boss strength. This ensures mechanical stability during high RPM operation. For tuners and engine builders, Forged Piston Modification Parts provide a reliable foundation for consistent power output and long-term durability, even under repeated load cycles.

2) How do High-Performance Forged Pistons improve engine reliability under conditions?

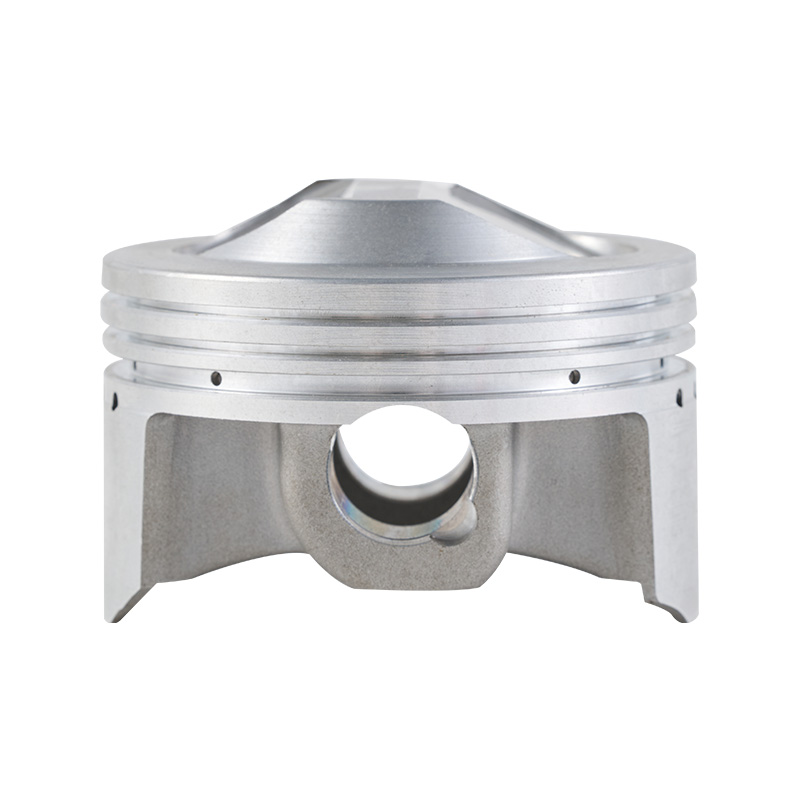

High-Performance Forged Pistons are specifically engineered to handle conditions where thermal stress and mechanical load exceed standard engine design limits. At Zhengji, these pistons are developed with real-world performance environments in mind.

One major advantage of High-Performance Forged Pistons is their outstanding resistance to thermal expansion. Through optimized alloy selection and precise forging pistons techniques, the piston maintains dimensional stability even during rapid temperature fluctuations. This reduces the risk of scuffing, seizure, or micro-cracking.

Compared with conventional performance pistons, forged versions offer stronger ring groove support and reinforced pin areas. This is essential for engines running higher boost or advanced ignition timing. Additionally, High-Performance Forged Pistons allow more aggressive combustion chamber designs, helping improve power without sacrificing reliability.

For applications where engine failure is not an option, High-Performance Forged Pistons become a long-term investment rather than a short-term upgrade.

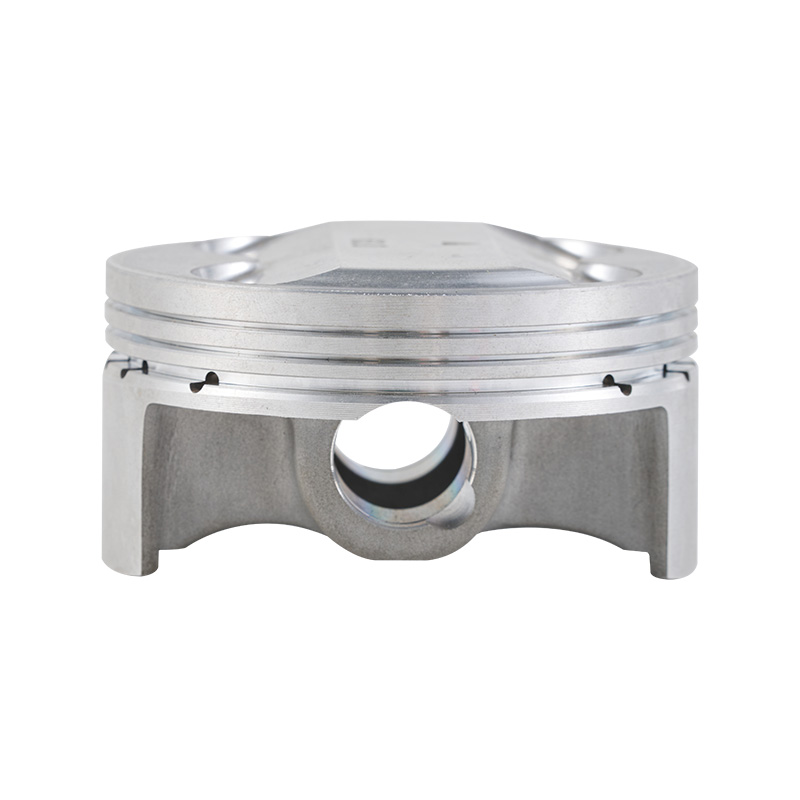

3) What makes Zhengji's forging pistons suitable for performance-oriented modifications?

Zhengji's expertise in forging pistons lies in process control and structural optimization. Forging is not just about strength—it's about directing material flow to support stress-critical areas.

During the forging pistons process, aluminum grains are compressed and aligned according to piston geometry. This internal structure provides significantly higher impact resistance than cast alternatives. As a result, these pistons outperform standard performance pistons in endurance and load-bearing capability.

Another advantage of Zhengji's forging pistons is design flexibility. Wall thickness, skirt profile, and crown shape can be optimized for specific performance goals, whether acceleration, sustained high-speed operation, or endurance racing. This makes them ideal for Forged Piston Modification Parts used in competitive or heavily tuned engines.

By combining manufacturing precision with application-driven engineering, Zhengji ensures that forging pistons meet both performance expectations and mechanical safety margins.

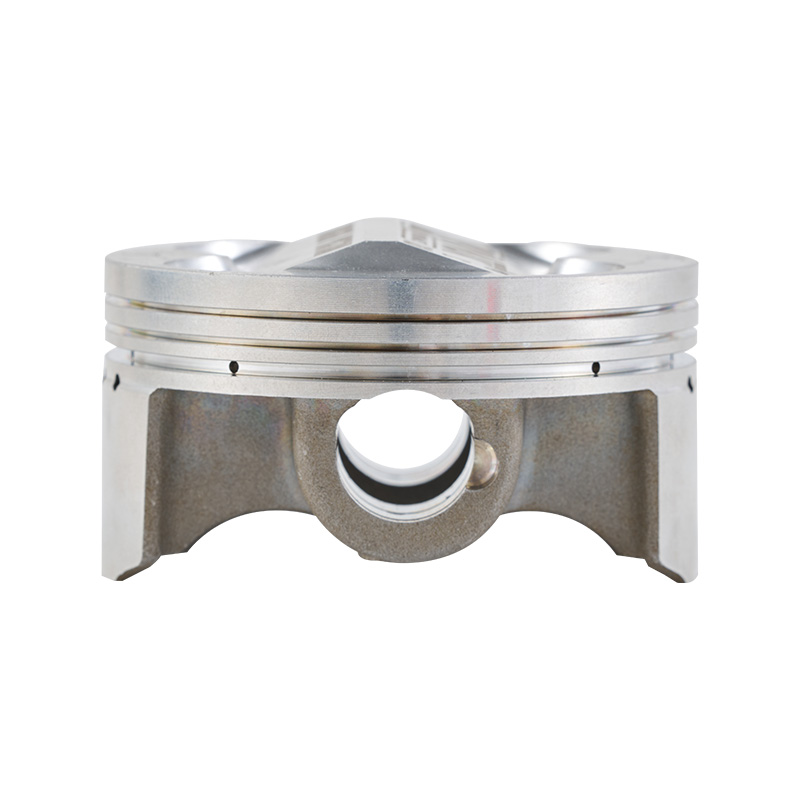

4) When should performance pistons be upgraded to forged solutions?

Not all engines require forged upgrades, but there are clear indicators when performance pistons should transition to forged alternatives. From Zhengji's experience, once power output, RPM range, or thermal load exceeds factory parameters, forged solutions become necessary.

Standard performance pistons may handle mild upgrades, but under high boost or track conditions, fatigue risk increases rapidly. Forged Piston Modification Parts address this gap by offering enhanced structural strength and better heat resistance. This is particularly important for engines used in motorsports, performance street builds, or long-duration high-load operation.

High-Performance Forged Pistons are also recommended when reliability matters as much as peak power. Through advanced forging pistons processes, these pistons reduce deformation and maintain sealing integrity over time.

In summary, upgrading from conventional performance pistons to forged solutions is a strategic decision driven by performance goals, engine safety, and long-term durability.

Typical Applications Comparison

| Application Scenario |

Recommended Solution |

| Mild street upgrade |

Performance pistons |

| High boost engines |

Forged Piston Modification Parts |

| Racing / track use |

High-Performance Forged Pistons |

| Long high-load cycles |

Forging pistons design |

Français

Français 中文简体

中文简体 Español

Español