Cast Piston Modification Parts Industry Knowledge Extension

1) Why are Cast Piston Modification Parts still widely chosen for engine modification projects?

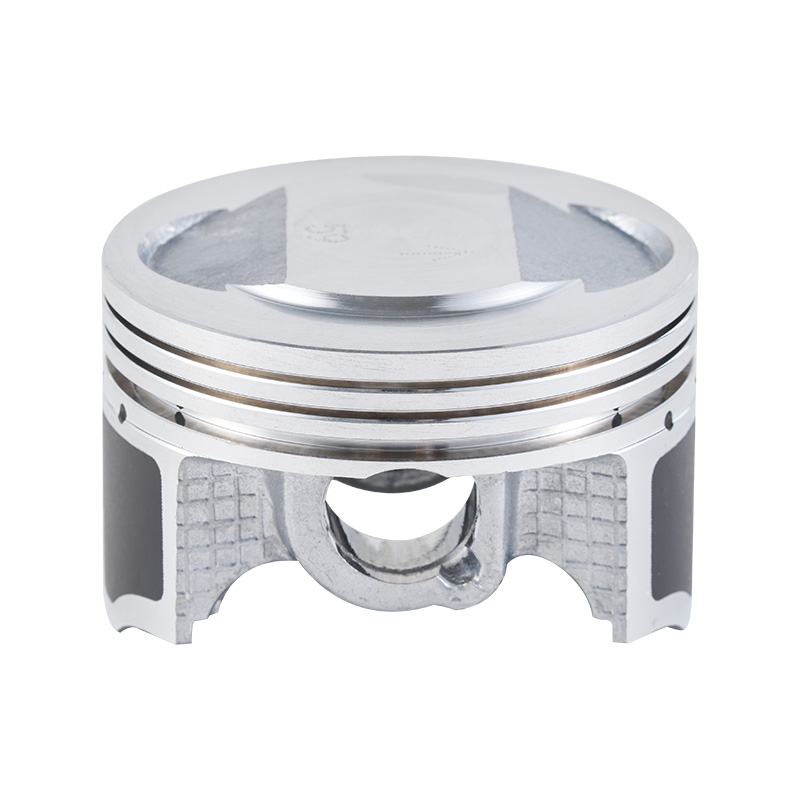

In many real-world applications, Cast Piston Modification Parts remain a highly practical solution for engine modification. While performance builds often focus on forged components, a large portion of the market requires balanced performance, cost control, and production stability.

From Zhengji's manufacturing experience, Cast Piston Modification Parts are ideal for engines operating within controlled RPM and temperature ranges. Through mature casting Pistons processes, we achieve consistent wall thickness, accurate dimensions, and stable mechanical properties. This allows engines to deliver reliable power without unnecessary material cost.

Another key advantage of Cast Piston Modification Parts is compatibility with traditional sealing systems, especially when paired with a cast iron piston ring. This combination provides dependable compression and oil control for daily-use vehicles, fleet engines, and light commercial applications.

2) How does Zhengji optimize casting Pistons for durability and consistency?

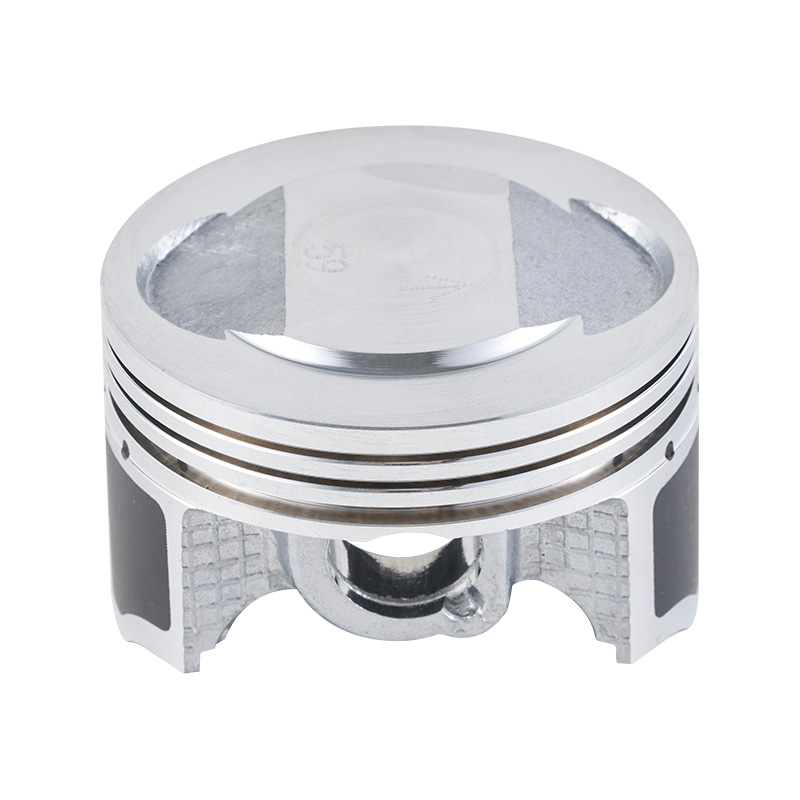

The quality of casting Pistons depends heavily on process control and tooling precision. At Zhengji, casting technology is refined to ensure repeatability across large production volumes.

Our casting Pistons are produced using carefully selected aluminum alloys that balance thermal conductivity and wear resistance. Mold design and cooling control reduce internal porosity, ensuring stable strength throughout the piston body. This is particularly important for engines designed for long service intervals.

Compared with overly aggressive performance-focused components, well-engineered casting Pistons deliver predictable expansion behavior. When matched with a cast iron piston ring, the piston-ring system maintains stable sealing over time. This makes Cast Piston Modification Parts a dependable option for customers prioritizing durability and supply consistency.

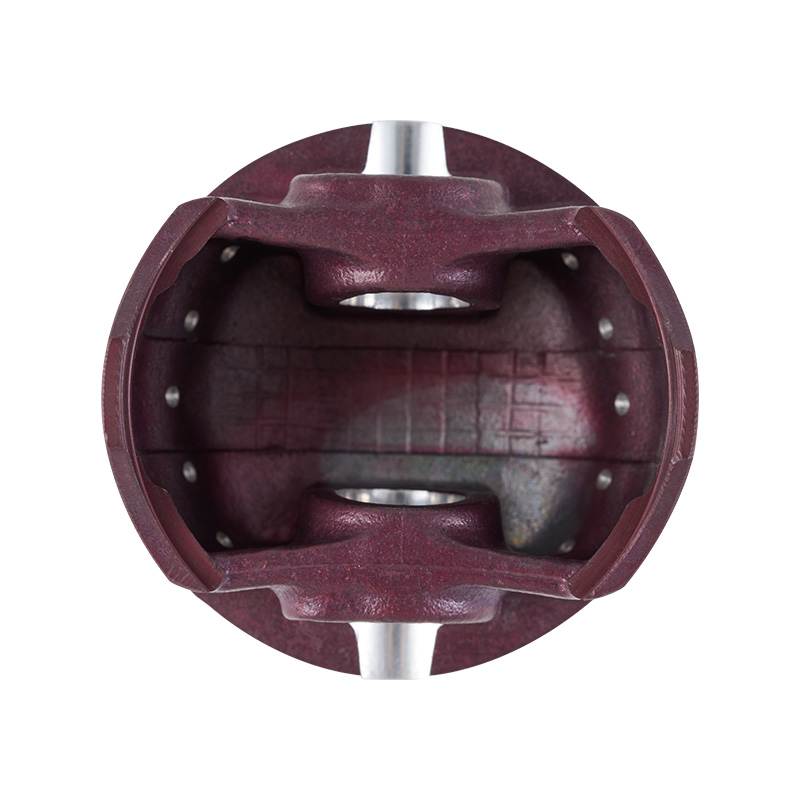

3) What role does the cast iron piston ring play in cast piston systems?

The cast iron piston ring remains a critical component in cast piston assemblies due to its proven wear resistance and sealing capability. In many standard and modified engines, the cast iron piston ring offers an good balance between friction control and longevity.

Zhengji designs piston grooves specifically to match cast iron piston ring characteristics. Proper groove geometry ensures stable ring movement and even contact with the cylinder wall. This synergy improves oil control and reduces blow-by, especially in engines with moderate operating stress.

When combined with Cast Piston Modification Parts, the cast iron piston ring enhances system reliability for daily driving, commercial use, and long-duration operation. This pairing is particularly effective in engines where maintenance intervals and cost efficiency are key decision factors.

4) What customization services does Zhengji offer for Cast Piston Modification Parts?

Customization is not limited to high-performance segments. Zhengji provides tailored solutions for Cast Piston Modification Parts to meet diverse engine and market requirements.

Customization options include:

- Dimensional adjustments: Bore size, compression height, and pin specifications

- Crown design tuning: Flat or mildly contoured crowns for combustion stability

- Skirt profile optimization: Noise reduction and improved lubrication behavior

- Ring compatibility: Precise matching with cast iron piston ring standards

Through controlled casting Pistons production, customized designs can be scaled efficiently without sacrificing consistency. This approach allows customers to maintain product differentiation while benefiting from stable mass production.

5) Which applications benefit from cast piston–based modification solutions?

From Zhengji's perspective, Cast Piston Modification Parts are suited for engines where reliability, affordability, and availability outweigh output demands.

Typical applications include:

| Application Type |

Recommended Configuration |

| Daily passenger vehicles |

Casting Pistons + cast iron piston ring |

| Light commercial engines |

Reinforced Cast Piston Modification Parts |

| Fleet and utility use |

Stable casting Pistons systems |

| Engine rebuild programs |

Cast Piston Modification Parts with standard rings |

In these scenarios, casting Pistons provide predictable performance and easier long-term supply planning. When paired with a cast iron piston ring, the system supports consistent engine behavior across extended service cycles.

Français

Français 中文简体

中文简体 Español

Español