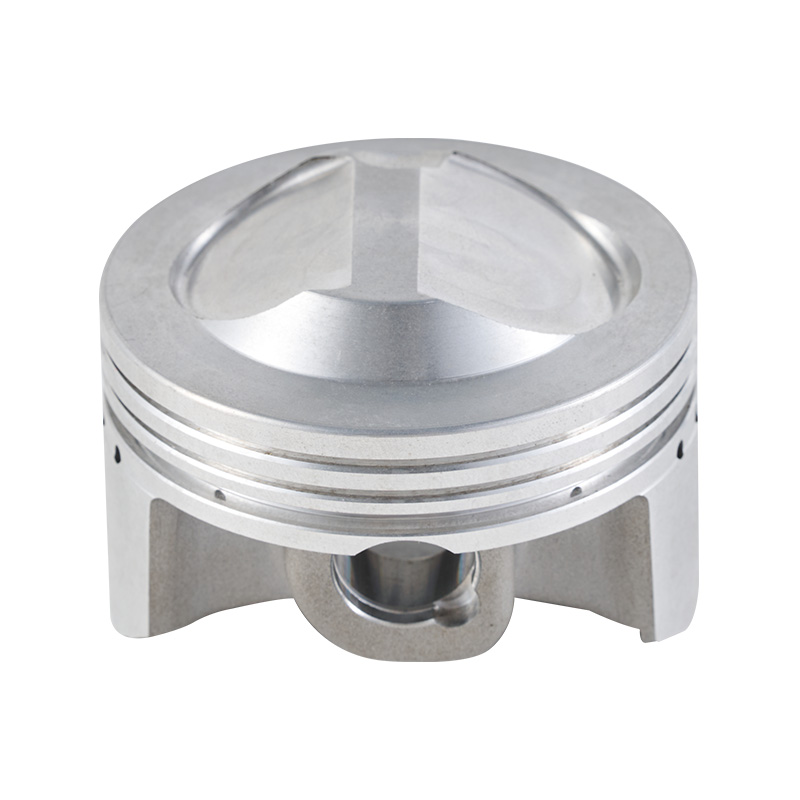

OEM Custom Piston Industry Knowledge Extension

1) What defines Zhengji as a reliable Custom Piston Manufacturer for modern engines?

As a Custom Piston Manufacturer, Zhengji focuses on building pistons that are engineered around real engine operating conditions rather than generic templates. Every custom piston project starts from application analysis—load, speed, temperature, and fuel behavior.

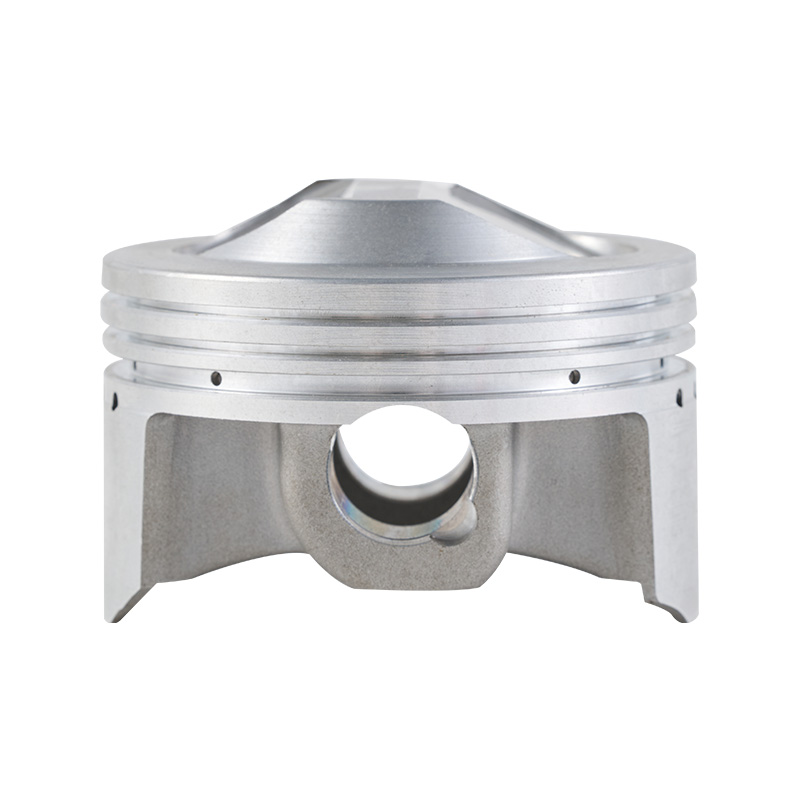

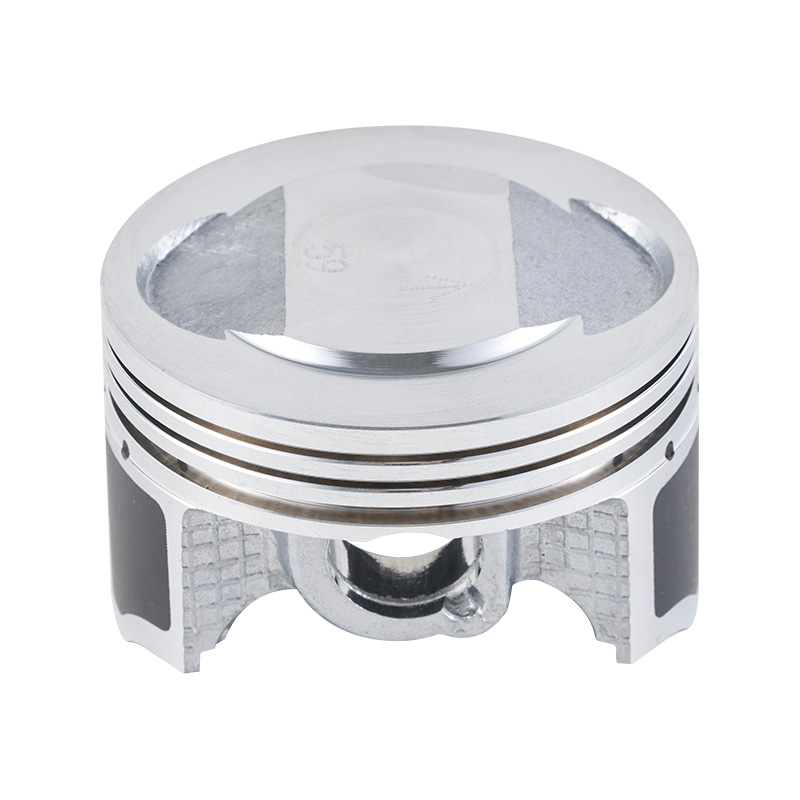

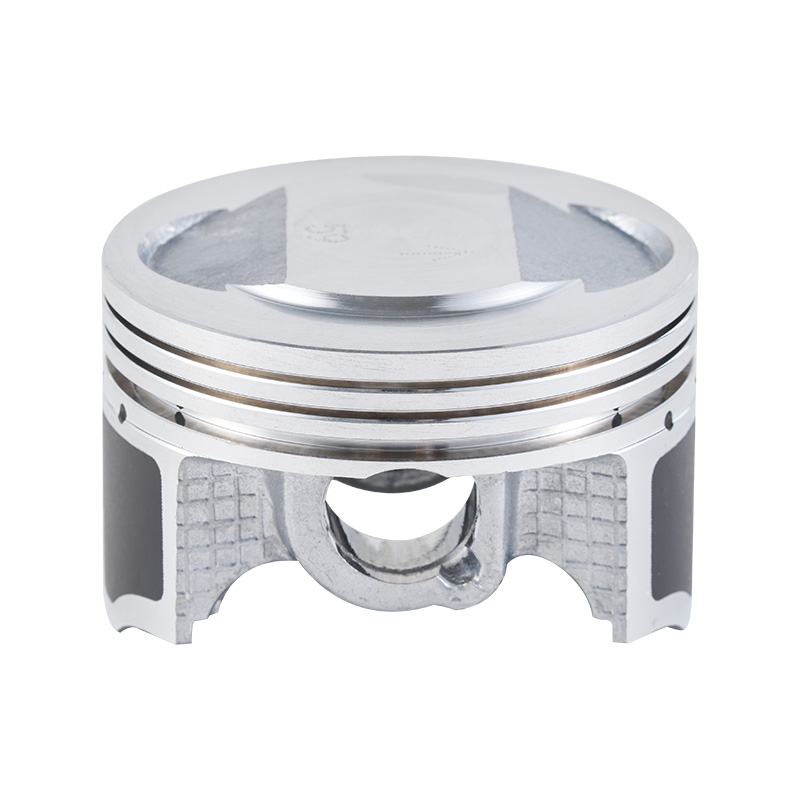

Key strengths include:

- Application-driven design: Pistons are developed according to engine type, whether for passenger vehicles, motorcycles, or specialized engines.

- Flexible structure control: Compression height, crown geometry, skirt profile, and pin offset can be precisely adjusted.

- Material selection expertise: Different aluminum alloys are chosen to balance strength, thermal expansion, and wear resistance.

- Consistency in batch production: Once a custom design is confirmed, mass production maintains the same dimensional stability.

This approach ensures that custom pistons are not just compatible, but optimized for long-term engine performance.

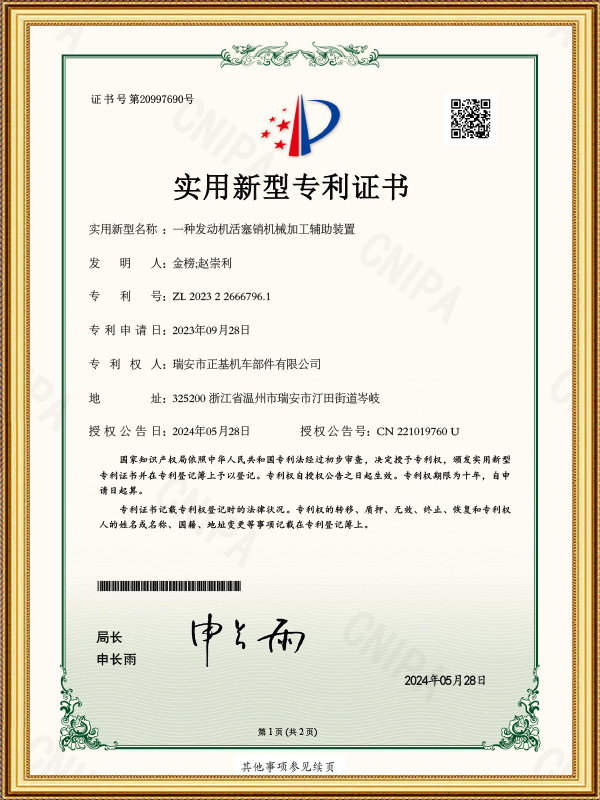

2) How does Zhengji support OEM customers beyond standard piston supply?

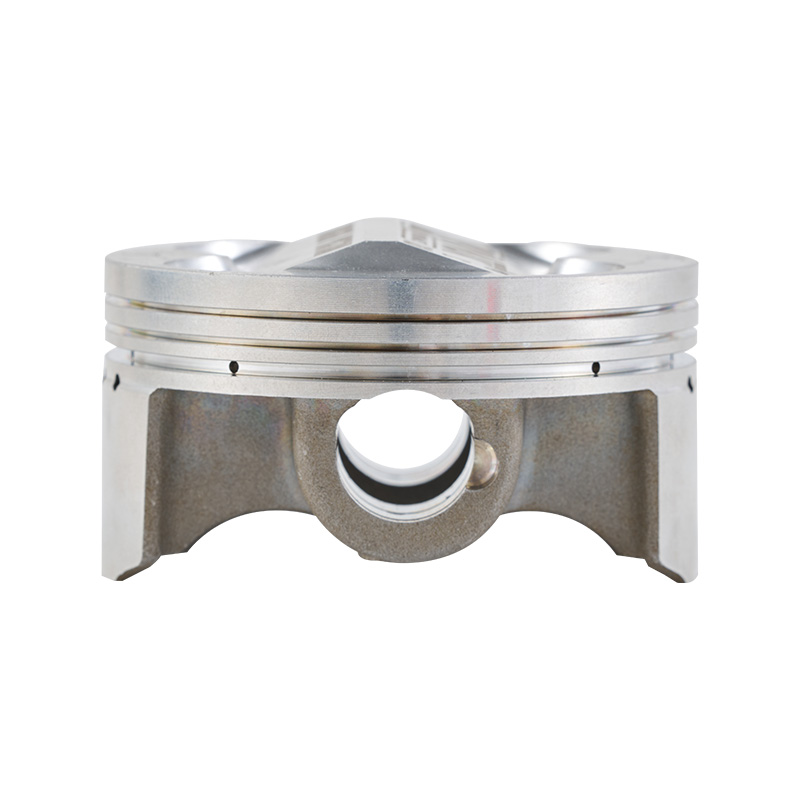

As an experienced OEM Piston Manufacturer, Zhengji acts as a technical partner rather than only a component supplier. Our OEM service covers the entire lifecycle from concept to mass delivery.

OEM support highlights:

- Design validation: OEM drawings or samples are analyzed and optimized for manufacturability and durability.

- Process customization: Machining tolerance, heat treatment, and surface finishing are aligned with OEM standards.

- Brand integration: Custom markings, laser codes, and packaging configurations are available for OEM branding.

- Scalable production: From pilot batches to high-volume orders, output remains stable and traceable.

This integrated OEM capability helps customers shorten development cycles while maintaining product differentiation in competitive markets.

3) What engine applications are Zhengji pistons engine parts suited for?

Zhengji's pistons engine parts are designed to serve a wide range of engine platforms, from standard replacement to performance-oriented applications.

Typical application areas include:

- Passenger vehicles: Daily-use engines requiring quiet operation, thermal stability, and fuel efficiency.

- Motorcycles and small engines: Lightweight pistons with precise balance for high RPM environments.

- Commercial and utility engines: Reinforced piston structures for sustained load and extended operating hours.

- Rebuild and upgrade markets: Oversize and application-specific pistons for worn or modified engines.

By tailoring piston geometry and material properties, Zhengji ensures compatibility with both original engine designs and aftermarket performance needs.

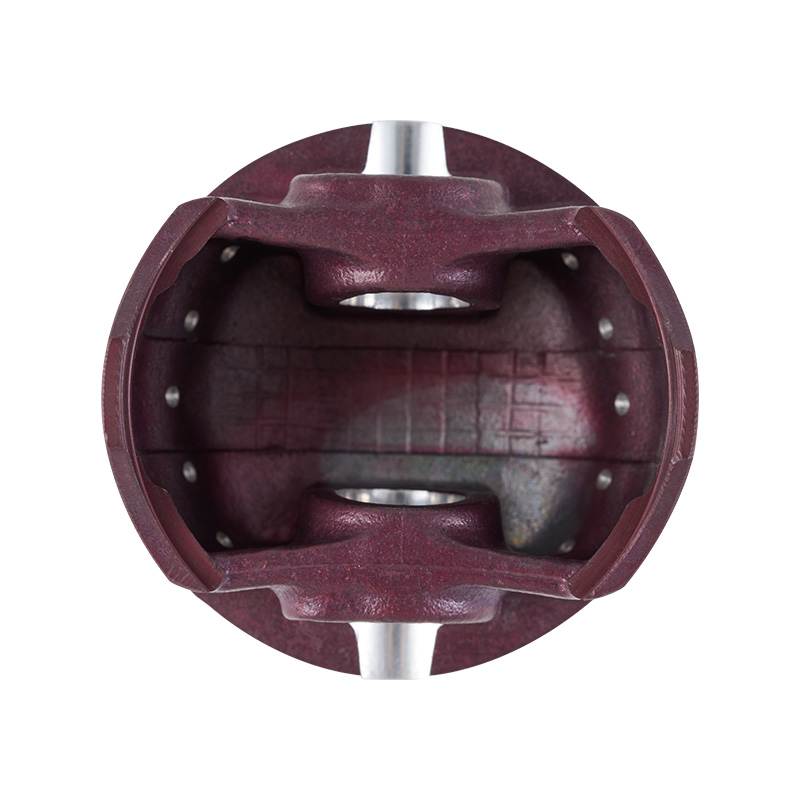

4) What customization options are available for pistons engine parts at Zhengji?

Customization is a core capability at Zhengji. Each piston can be adapted to meet specific technical or market requirements.

Common customization parameters include:

| Custom Item |

Customization Options |

| Piston Crown |

Flat, dome, bowl, special combustion shapes |

| Skirt Design |

Anti-friction profiles, noise-reduction structures |

| Ring Grooves |

Width, depth, and positioning customization |

| Piston Pin |

Diameter, length, and offset variations |

| Surface Treatment |

Optional coatings for wear or friction control |

These options allow customers to fine-tune engine response, durability, and assembly compatibility without redesigning the entire engine system.

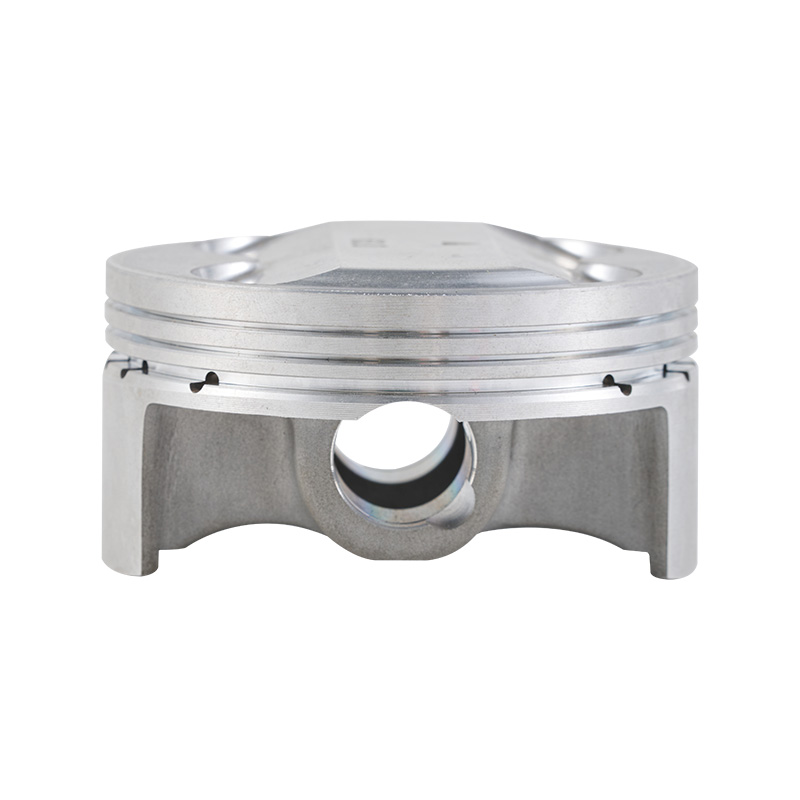

5) How does Zhengji ensure quality stability for custom and OEM piston production?

Quality stability is essential for both custom and OEM piston programs. Zhengji integrates quality control throughout every production stage.

Quality assurance measures include:

- In-house machining control: Key processes are handled internally to minimize variation.

- Precision inspection: Dimensional accuracy, weight balance, and surface finish are carefully verified.

- Batch traceability: Each production run is documented for consistent repeat orders.

- Performance-oriented testing: Pistons are evaluated against mechanical and thermal requirements before approval.

This system ensures that every piston delivered—whether a custom design or OEM order—meets the same performance expectations as the original specification.

Français

Français 中文简体

中文简体 Español

Español