We start by understanding the product's application, operating conditions, and engine platform specifications.

-

01Requirement Discussion

-

02Preliminary Proposal

Our engineers provide initial design suggestions, including structure options, material recommendations, and surface treatment processes.

-

03Drawing & Technical Confirmation

Detailed drawings are created by our engineering team and finalized in consultation with the customer.

-

04Prototype Development

We proceed with mold making, prototype production, and preliminary performance testing.

-

05Customer Validation

Test reports are delivered, and we assist with bench or full-system testing as needed.

-

06Mass Production

Once the prototype is approved, we move into volume production with a stable supply plan.

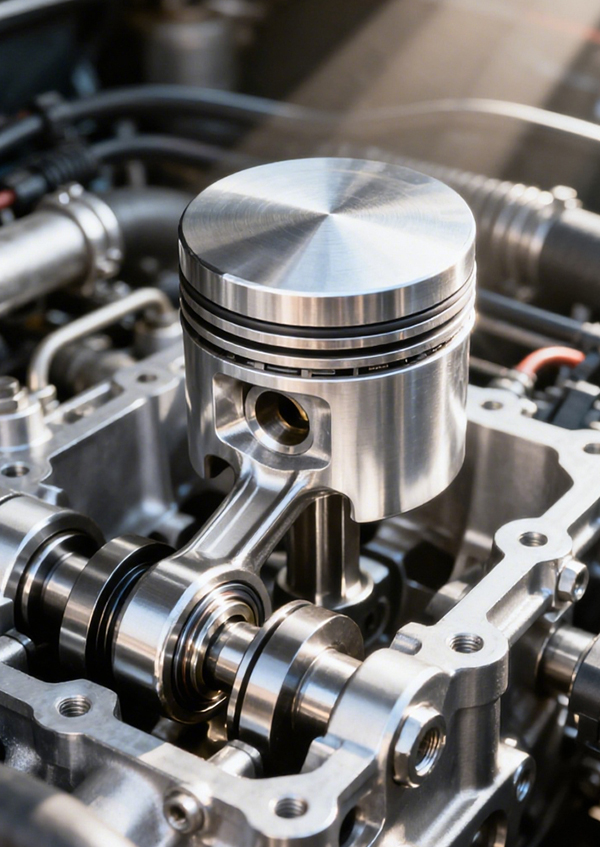

We have extensive experience in piston and piston ring design and manufacturing, offering customized services across a wide range of cylinder bore sizes, structural styles, and surface treatments.

We have developed over xx product models, widely used in motorcycle engines, small gasoline engines, passenger car and light commercial vehicle engines, general machinery, and agricultural power systems.

Cylinder diameter range: 16.5 mm to 150 mm

Piston material: High-silicon aluminum alloy, AlSi12CuNiMg, etc

Piston ring material: Ductile iron, alloy steel, stainless steel

Adaptable to engine platform cylinder diameter/height/groove/pin hole/material/surface treatment

Customization

-

Data Submission

Customers provide 2D/3D drawings or physical samples.

-

Technical Review

Our engineering team evaluates feasibility and develops the optimal manufacturing approach.

-

Tooling & Fixture Preparation

If required, we develop molds and configure fixtures accordingly.

-

Sample Fabrication

Prototypes are precision-machined according to specifications and internally inspected.

-

Customer Evaluation

Customers assess the sample’s quality and fit for assembly.

-

Mass Production

After final confirmation, we move to full-scale production and ensure timely delivery.

Français

Français 中文简体

中文简体 Español

Español