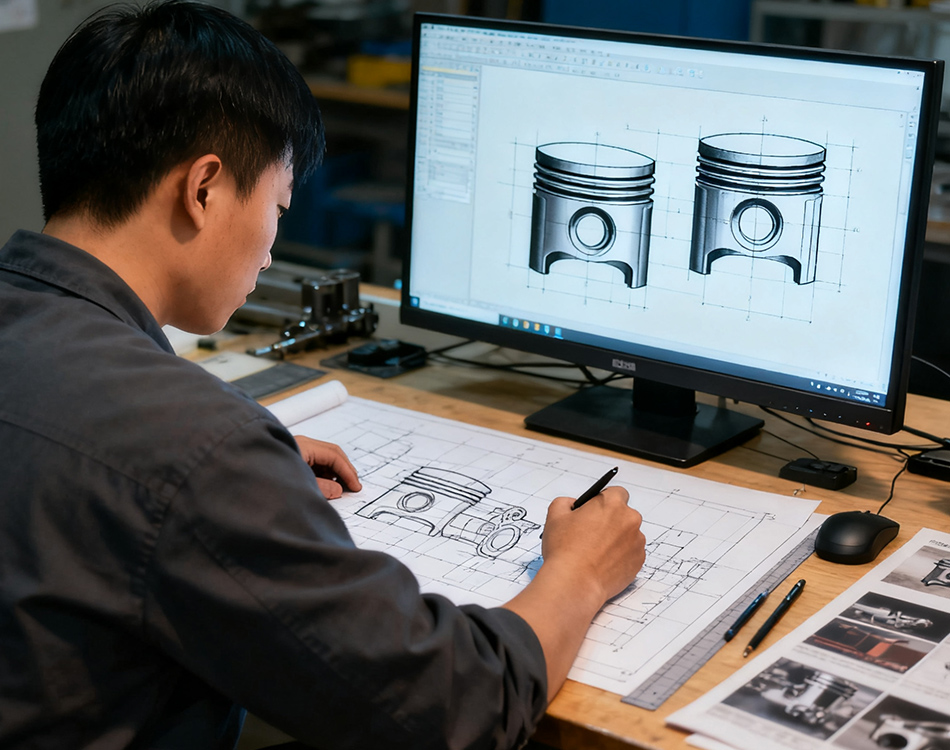

Ruian Zhengji Motorcycle Parts Co., Ltd. is a specialized manufacturer engaged in the research, development, production, and sales of pistons for automobiles, motorcycles, and outboard engines. In addition to offering standard piston products, we focus on the development of motorcycle modification parts and customized products to meet the diverse needs of our customers.

We possess a complete production chain from blank casting to finished piston manufacturing, equipped with over 200 advanced production machines, including more than 80 high-precision CNC lathes. During the piston manufacturing process, we employ both casting and forging techniques to ensure durability and performance. The forging process provides pistons with greater strength and wear resistance, while the casting process offers higher production efficiency and flexibility.

-

Industry development years

0+ -

Assembly Line

0+ -

Product Range

0+ -

Factory Area(square meters)

0+

R&D

-

Material Optimization

Material OptimizationCommitted to the application and advancement of high-temperature and wear-resistant aluminum alloys and gray cast iron materials.

-

Surface Treatment Technologies

Surface Treatment TechnologiesSupport for surface enhancement processes such as nitriding, PVD, and DLC to improve wear resistance and friction performance.

-

Structural Design and Simulation

Structural Design and SimulationCapable of providing casting simulation, thermal analysis, and fatigue life evaluation for structural optimization.

-

Rapid Development Support

Rapid Development SupportCustomization available based on drawings or samples, with quick turnaround for prototype production and adjustments.

-

Performance Testing Support

Performance Testing SupportComprehensive testing for elasticity, hardness, coating thickness, and more to ensure stable and reliable product quality.

OUR VALUES

● The core of manufacturing lies not in machinery, but in the unwavering commitment to quality and attention to detail. For years, we have focused on the specialized field of pistons and piston rings, continuously refining every process to ensure each product is more reliable and stable.

● Expertise comes from dedication, and service stems from understanding. Whether it's standard components or custom-developed parts, we always prioritize our customers’ needs. From structure to materials, dimensions to surface treatment, we strive for excellence in every detail.

Français

Français 中文简体

中文简体 Español

Español